Product Description

Production Description

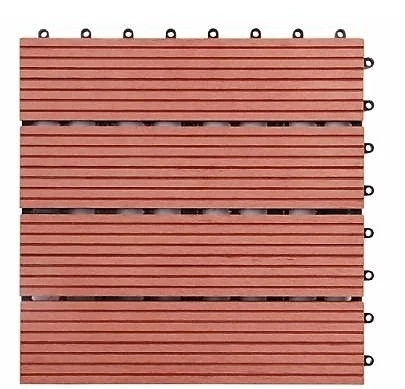

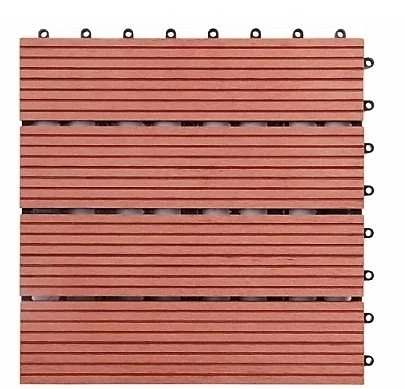

Kelai DIY WPC decking is made of 60% wood fiber,30%HDPE and 10% additives.

These all material are very friendly.And the decking is anti-slip,anti-uv,crack resistant,anti-corrosion,anti-deformation,heat resistant and anti-mite.However the important thing is that the wpc decking doesn't need any maintance.

Surface : Stripe sanding

Feature

1.Our diy decking with high density,high strength and good looking.

2.Our diy decking is non absorbent,effectively prevent the decay and damage.

3.Our diy decking advocates environmental protection,back to nature.

4.Our diy decking creates beautiful and comfortable land.

5.Our diy decking is anti-corrosion,anti-crack,anti-deformation.

6.Our diy decking is easy to install and clean.

Colors

Storage and Maintenance

1.Please don't arbitrarily stack when discharge WPC materials.

2.Because of the possibility of deformation of composite decking, so please don't vertically discharge, and please level on the ground when storage WPC decking.

3.Place on the plane, should prevent the rain, please use the protective material to cover.In order to get better supporting effect, please support to the edge when transport WPC decking.

4.When put on the hard ground, there should have suitable material to underlay at the bottom, please pay attention to the cutting ends and don't have impact phenomenon.

5.Don't have a hammer and other hard things fall impact,all these may cause WPC products damaged.

6.When move WPC decking material, we should avoid mutual sliding friction. Move out from the whole stack,and should lift,then place.

7.When install WPC decking, please don't let tools, screws or tools equipment sliding on the decking surface.

8.Avoid WPC decking touch with the building waste.

9.After the scrape, WPC chip contain resin component , so we shouldn't treat it as burning garbage disposal, please deliver the debris and other waste materials to factory for recycle, not only it can protect our earth, but it also realize WPC material recycling.

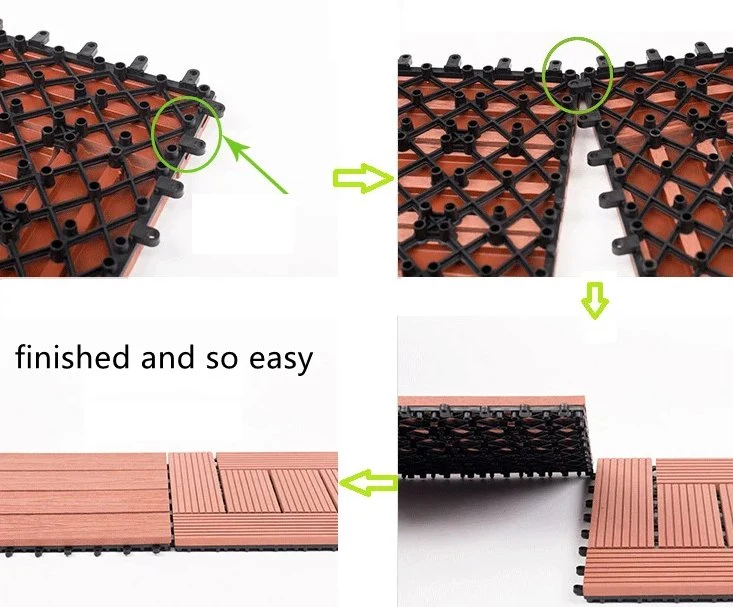

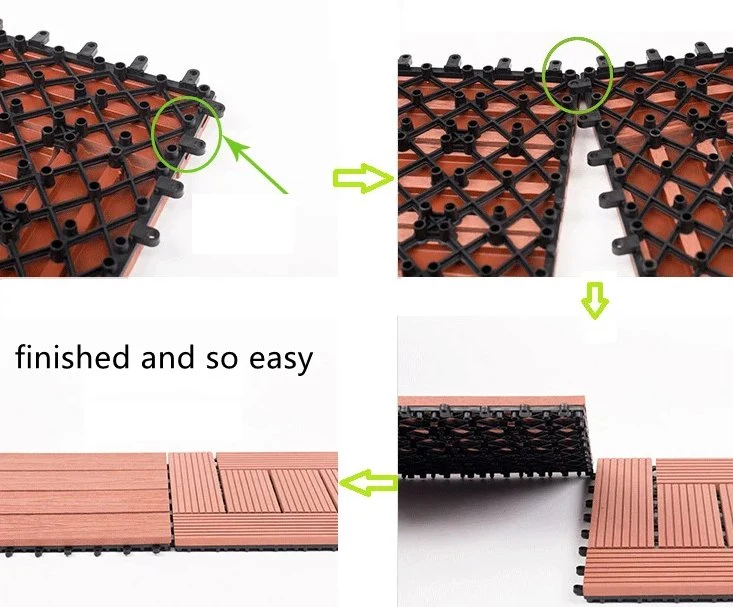

Installation Instruction

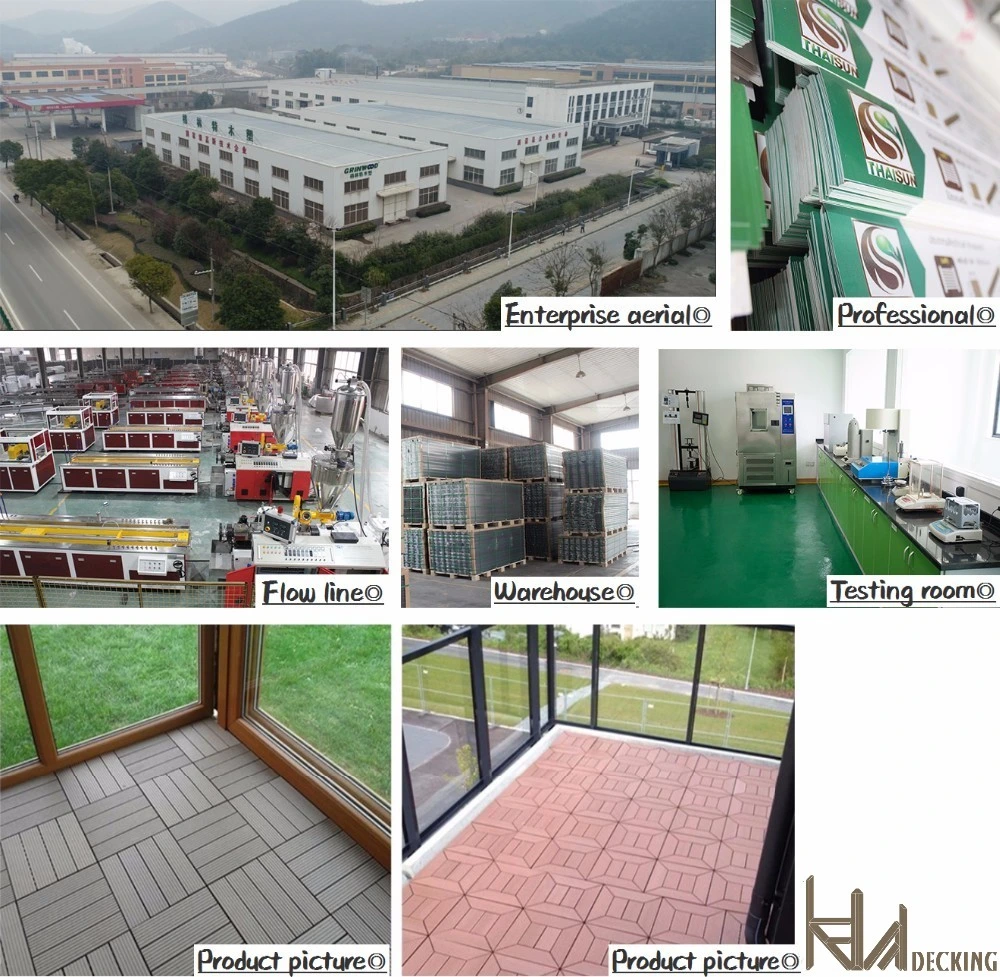

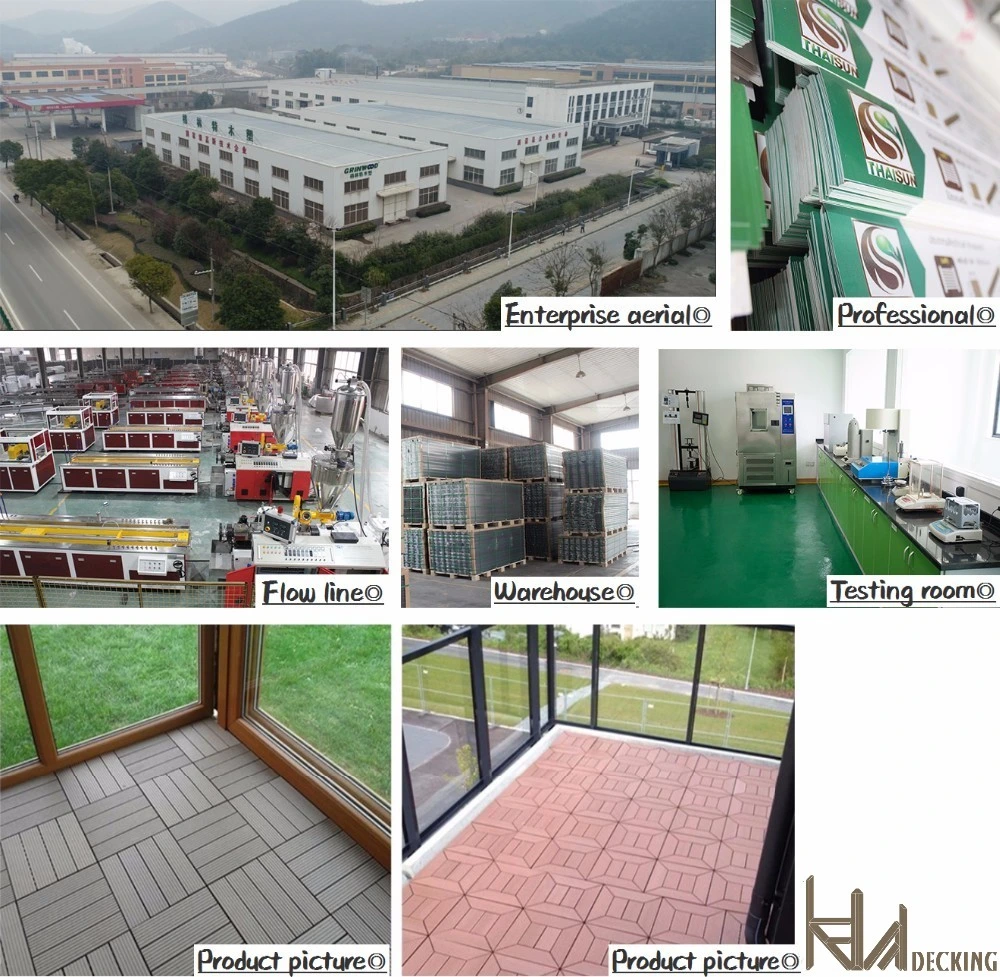

Enterprise Display

Kelai was created to bring you the best flooring products from China.Our Team of professionals have many years of experience in the export and domestic market. Kelai is selling our flooring to more than 30 countries around the world, like USA, Canada, Mexico, etc.

Packing

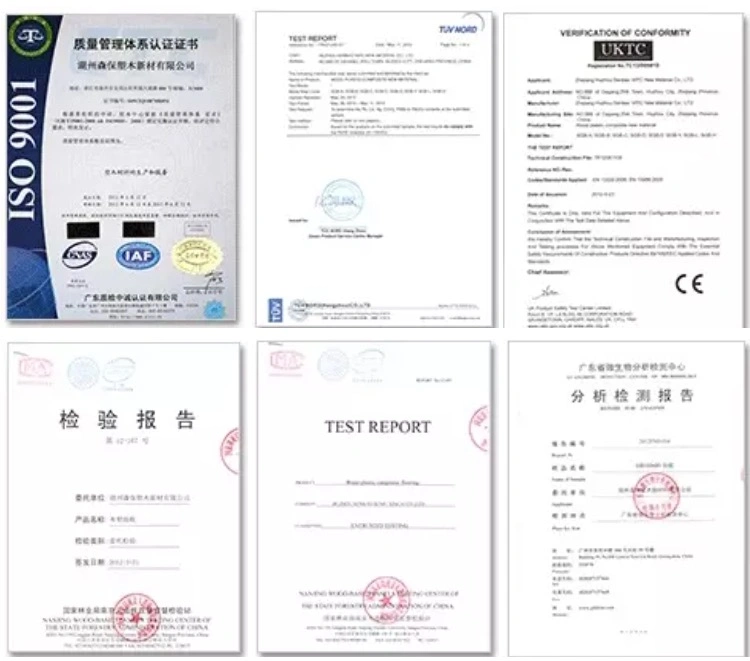

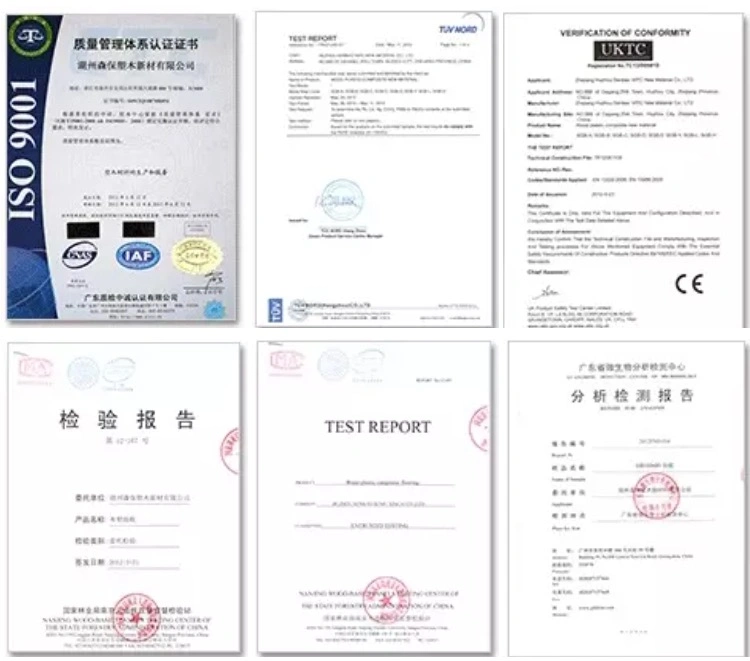

Certification

FAQ

Q: What is the species of wood fiber you use?

A: Eucalyptus, poplar and some mixed wood, which is color related.

Q: What about your main market?

A: The main market is always oversea. More than 90% of the products are for export, and main market is Greece, Czech Republic,Italy,Germany, Spain, Austria, Swiss, Estonia, Norway, UK, Korea, Thailand, Indonesia, Vietnam, USA, Canada, Argentina,Australia,etc.

Q: Do your WPC products have color fading problem?

A: To be honest, the products do have some color fading problem mostly during the first 6 months after installation, but not obvious.

Q: How many production lines you have? What about the production capacity per month?

A: 30 extrusions lines. 60 containers per month.

Q: What properties will you test for your raw material and end products?

A: Wood fiber: ash content, fiber size, water content.

HDPE: melting index, ash content, physical property test for finish product.

End product: melting index, ash content, physical property test for finish product.

End product: strength test, boiling test and expansion rate test, temperature cycle test, outdoor UV test.

Q: What about delivery time for one container?

A: 15-20 days upon deposit payment well received.

Q:What about the temperature range of your WPC can be used?

A: -40 to 60 degrees.

Q: Have you ever received any complaints from your customers?

A: Frankly speaking, yes. And it's mainly about color difference, cause our raw material is recycled material, there is always difference between different lots. Now mixing is done for our HDPE plastic and also after pelletizing to well control of this problem.

Kelai DIY WPC decking is made of 60% wood fiber,30%HDPE and 10% additives.

These all material are very friendly.And the decking is anti-slip,anti-uv,crack resistant,anti-corrosion,anti-deformation,heat resistant and anti-mite.However the important thing is that the wpc decking doesn't need any maintance.

Surface : Stripe sanding

| Type | WPC DIY decking |

| Technic | Wood Plastic Composite |

| Size | 300*300*22mm |

| Surface | Stripe sanding |

| Model | BS-06 |

| Delivery Time | 15-20 days after we received the deposit |

| Certification | ISO9001/Intertek/TUV/CE/ISO14001 |

| Application | pond surrounds, paths, patios or balconies |

Feature

1.Our diy decking with high density,high strength and good looking.

2.Our diy decking is non absorbent,effectively prevent the decay and damage.

3.Our diy decking advocates environmental protection,back to nature.

4.Our diy decking creates beautiful and comfortable land.

5.Our diy decking is anti-corrosion,anti-crack,anti-deformation.

6.Our diy decking is easy to install and clean.

Colors

Storage and Maintenance

1.Please don't arbitrarily stack when discharge WPC materials.

2.Because of the possibility of deformation of composite decking, so please don't vertically discharge, and please level on the ground when storage WPC decking.

3.Place on the plane, should prevent the rain, please use the protective material to cover.In order to get better supporting effect, please support to the edge when transport WPC decking.

4.When put on the hard ground, there should have suitable material to underlay at the bottom, please pay attention to the cutting ends and don't have impact phenomenon.

5.Don't have a hammer and other hard things fall impact,all these may cause WPC products damaged.

6.When move WPC decking material, we should avoid mutual sliding friction. Move out from the whole stack,and should lift,then place.

7.When install WPC decking, please don't let tools, screws or tools equipment sliding on the decking surface.

8.Avoid WPC decking touch with the building waste.

9.After the scrape, WPC chip contain resin component , so we shouldn't treat it as burning garbage disposal, please deliver the debris and other waste materials to factory for recycle, not only it can protect our earth, but it also realize WPC material recycling.

Installation Instruction

Enterprise Display

Kelai was created to bring you the best flooring products from China.Our Team of professionals have many years of experience in the export and domestic market. Kelai is selling our flooring to more than 30 countries around the world, like USA, Canada, Mexico, etc.

Packing

Certification

FAQ

Q: What is the species of wood fiber you use?

A: Eucalyptus, poplar and some mixed wood, which is color related.

Q: What about your main market?

A: The main market is always oversea. More than 90% of the products are for export, and main market is Greece, Czech Republic,Italy,Germany, Spain, Austria, Swiss, Estonia, Norway, UK, Korea, Thailand, Indonesia, Vietnam, USA, Canada, Argentina,Australia,etc.

Q: Do your WPC products have color fading problem?

A: To be honest, the products do have some color fading problem mostly during the first 6 months after installation, but not obvious.

Q: How many production lines you have? What about the production capacity per month?

A: 30 extrusions lines. 60 containers per month.

Q: What properties will you test for your raw material and end products?

A: Wood fiber: ash content, fiber size, water content.

HDPE: melting index, ash content, physical property test for finish product.

End product: melting index, ash content, physical property test for finish product.

End product: strength test, boiling test and expansion rate test, temperature cycle test, outdoor UV test.

Q: What about delivery time for one container?

A: 15-20 days upon deposit payment well received.

Q:What about the temperature range of your WPC can be used?

A: -40 to 60 degrees.

Q: Have you ever received any complaints from your customers?

A: Frankly speaking, yes. And it's mainly about color difference, cause our raw material is recycled material, there is always difference between different lots. Now mixing is done for our HDPE plastic and also after pelletizing to well control of this problem.