Basic Info.

Model NO.

SJSZ65/132

Engagement System

Full Intermeshing

Screw Channel Structure

Deep Screw

Exhaust

Exhaust

Automation

Automatic

Computerized

Non-Computerized

Voltage

380V 50Hz 3p

Power(W)

37kw Main Motor

Weight

12t

Raw Material

PVC+ASA or PMMA

Product Width

840mm

Product Thickness

2-3mm

After-Sales Service Provided

Engineers Available to Service Machinery Overseas

Packing

Film+Wooden Case, or Customized

Plastic Processe

PVC

Condition

New

Transport Package

Film+Wooden Case, or Customized

Specification

23*2*3M

Trademark

Weier

Origin

Shangdong

HS Code

84772090

Production Capacity

60 Sets/Year

Product Description

Recycled UPVC PVC ASA glazed roofing sheet machine

Specifications

1>Width: 720,880,1050mm

2>Thickness: 2-5mm

3>CE,ISO

recycled UPVC PVC ASA glazed roofing sheet machine

Product Description

1. Raw material & Final product of roofing sheet machine

2. Work condition (provide by customer) of roofing sheet machine

3. Energy consumption of roofing sheet machine

Product Specification

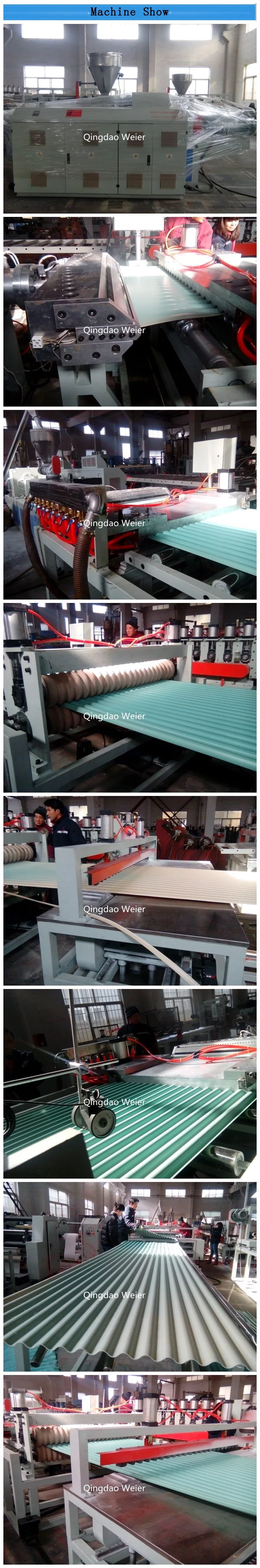

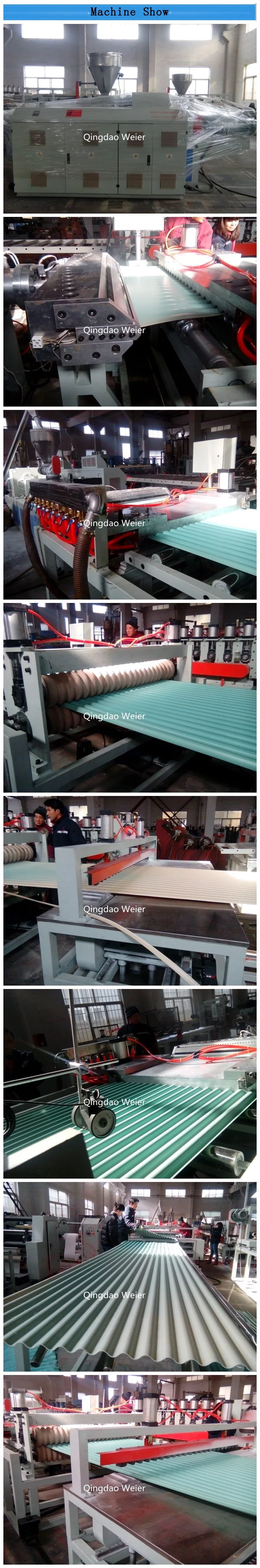

Glazed Tile Extrusion Line/Machine:

Glazed tile extrusion line/machine is consisted by following parts:

1) Extruder,

2) T-die and shaping downstream units,

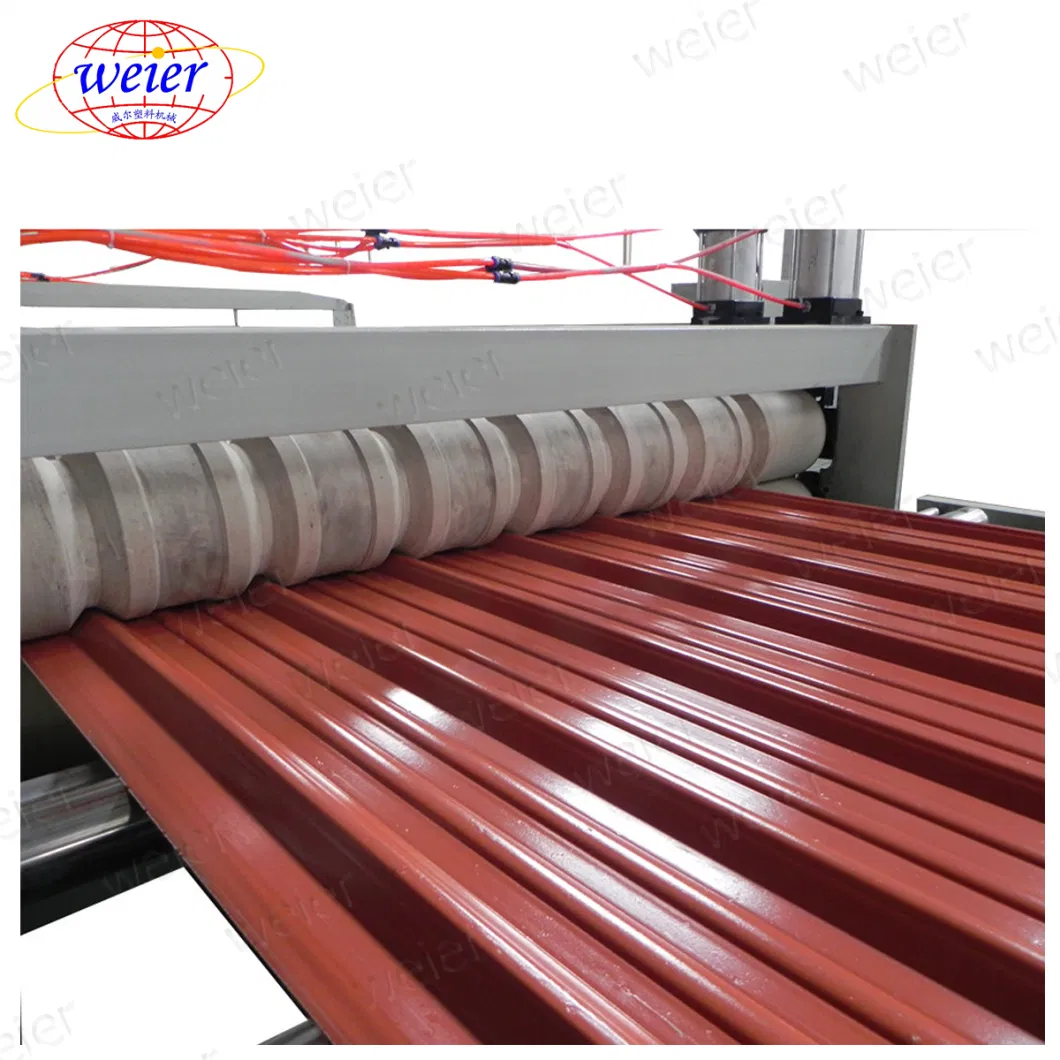

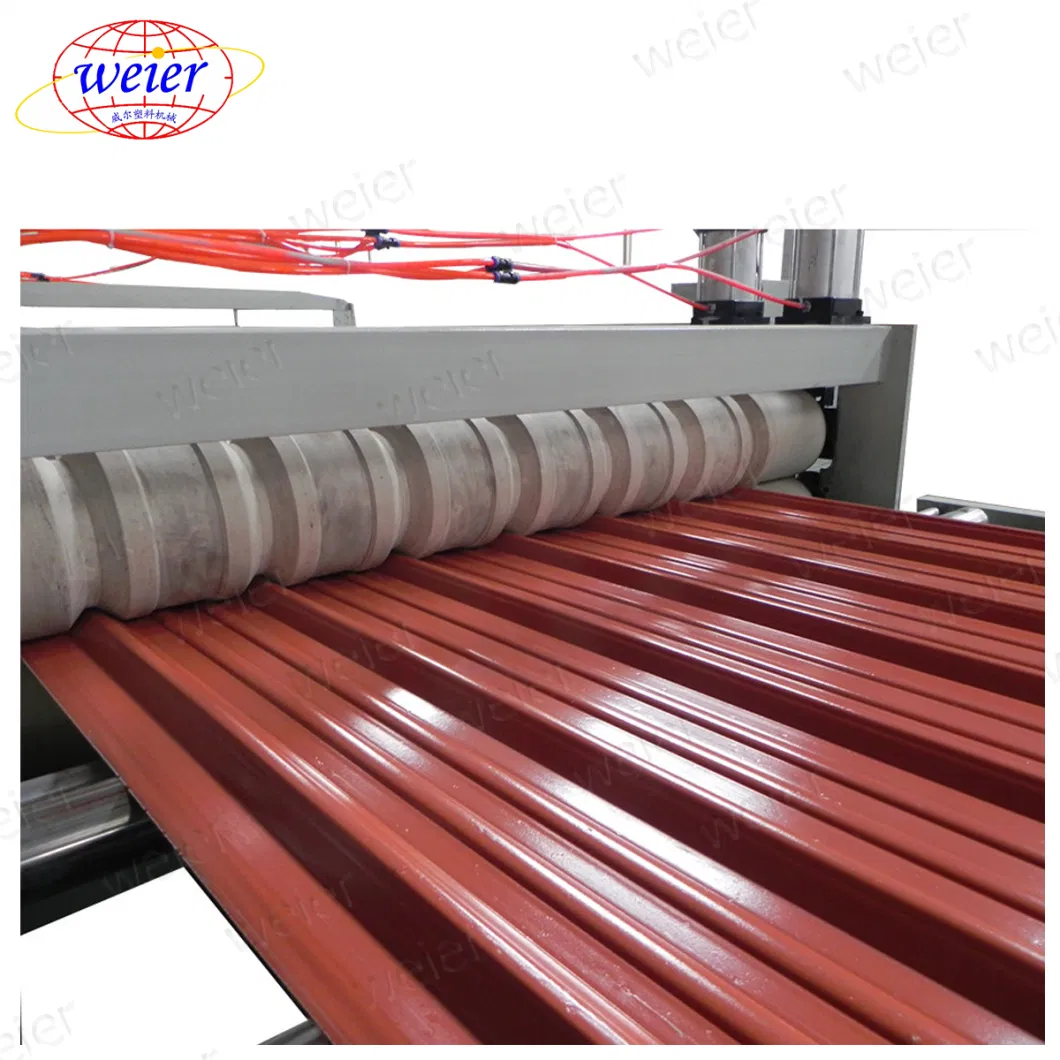

Which can continuous extruding synthetic resin tile, single layer PVC glazed tile, PVC/PMMA and

PVC/ASA composite multi-layer glazed tile

Glazed tile extrusion line/machine is mechanotronics, with the advantages of:

1) High production efficiency;

2) Reasonable structure compact;

3) Convenient operation and maintenance

4) Long use life etc.

Compare with ordinary plastic tile, glazed tile has more beautiful appearance, better quality, and

strong durability And some special features, such as anti-fire, anti-corrosion, anti-freeze, good weather

resistance and color retention,etc.

Application of concrete roof tile

Glaze roof tile and resin tile can be high-grade plants, steel factories, warehouses, farm market,

market access, sheds and other high-end roofing materials. Especially in corrosive chemical plants,

smelters, ceramic plants, soy sauce factory, chemical plants, printing and dyeing plant, organic solvent

factory, acid, alkali and other corrosive plant.

4. Main commercial terms

Our Services

Technology service and after-sale service

Specifications

1>Width: 720,880,1050mm

2>Thickness: 2-5mm

3>CE,ISO

recycled UPVC PVC ASA glazed roofing sheet machine

Product Description

1. Raw material & Final product of roofing sheet machine

| Raw material & formulation | PVC resin, Caco3, lubricant,stabilizing agent, pigment, anti-ultraviolet agent,Pigment etc |

| Central height: | 1000mm |

| Max. Haul-off speed: | 3m/min |

| Operation direction | From right to left (face to the operation panel) |

| Machine color | Standard color: RAL7016 (Anthracite grey) ; RAL9002 (Grey white) |

| Description final product & Output capacity | Singlelayers PVC Roofing tile; Width:500-1500mm,Thickness: 1.2~3.0mm; Wave distance:180mm; Wave height:30mm; Output:300-400kg/h(Depending on CaCO3 proportion) |

2. Work condition (provide by customer) of roofing sheet machine

| Warehouse/Workshop | Construction of foundations, construction works, earthworks, and wall works; Supply of cranes, fork-lifts or other lifting equipment; Mounting materials and tools; Dimension (M×M×M): 20 (Length)×2.0 (width) ×2.5 (Height) Crane: Machine positioning |

| Temperature & Humidity | ≤40°C, ≤95% |

| Power supply | Supply voltage: 3*380V+N+PE; Voltage tolerance: +5%/-5%; Control voltage: 24VDC+220VAC; Frequency: 50HZ+-2% |

| Wire/cables/water hose: | Wires/cables: from power supply to control cabinet of this production line and all electrical cables from control cabinet to each machine; Water hose: supply water to machines and pools; |

| Cooling Water | Without dissolved or suspended minerals as phosphor, sulphur, iron, etc. Inflow temperature T1: max. 15°C; Outflow temperature T2: T2=T1+5°C; Hardness: 5-8 OdH; Reflux: without pressure |

| Lubrication oil: | Sinopec, Exxon mobile |

| Compressor | Unnecessary |

3. Energy consumption of roofing sheet machine

| Installation power | 135KW,the real consumption only 80% |

| Cooling Water | ≤20°C, ≥0.3Mpa, ~4-5tons/hr |

| Compressedair | 0.3m3/min, >0.6Mpa |

| Manpower | 2-3 Person |

Product Specification

Glazed Tile Extrusion Line/Machine:

Glazed tile extrusion line/machine is consisted by following parts:

1) Extruder,

2) T-die and shaping downstream units,

Which can continuous extruding synthetic resin tile, single layer PVC glazed tile, PVC/PMMA and

PVC/ASA composite multi-layer glazed tile

Glazed tile extrusion line/machine is mechanotronics, with the advantages of:

1) High production efficiency;

2) Reasonable structure compact;

3) Convenient operation and maintenance

4) Long use life etc.

Compare with ordinary plastic tile, glazed tile has more beautiful appearance, better quality, and

strong durability And some special features, such as anti-fire, anti-corrosion, anti-freeze, good weather

resistance and color retention,etc.

Application of concrete roof tile

Glaze roof tile and resin tile can be high-grade plants, steel factories, warehouses, farm market,

market access, sheds and other high-end roofing materials. Especially in corrosive chemical plants,

smelters, ceramic plants, soy sauce factory, chemical plants, printing and dyeing plant, organic solvent

factory, acid, alkali and other corrosive plant.

4. Main commercial terms

| Project | PVC roofing tile extrusion line |

| Payment term | 30% as down payment by T/T; 70% by T/T before delivery and after inspection |

| Delivery time | 70 days since the date of receiving down payment |

| Packing | Wood pallet covered by plastic film |

| Warranty period | 13 months since date of bill of lading |

Our Services

Technology service and after-sale service

| Technology service | the supplier provide service manual and maintenance instruction of main electric appliance ,limb , usage manual of equipment, We also supply water,electricity,gas of equipment and installation drawing. |

| After-sale service | the supplier is responsible for installation,debug and training, we will realize guarantee of repair; replacement of substandard products within one year. After the machine leaves factory. Fittings of the machine will supply at preferential price after one year . |

| Debugging | The seller will send one or two technician to the buyer'plant to debugging, and the tickets ,eating ,transportation and visa fee will be paid by the buyer , also including 50USD salary/person /day |