Basic Info.

Model NO.

880, 1050, 1140mm

Customized

Customized

Condition

New, Under The Order

Warranty

1year

Pipe Types

PVC ASA Composite Glazed Roof Tile

Delivery Conditions

Fob CIF CIP

Processing Period

40-60 Days

Delivery Period

30days

After-Sales Service

Send Engineers Install and Test Machine

Technical Support

Permanent

Dimension

20*4.0*3 (M)

Weight

12t

Output

350-400kg/H

Transport Package

Stretch Film and Wooden Pallet, Wooden Packing

Specification

PVC ASA glazed roof tile Width 720/880/960/1040mm

Trademark

Sincere Machinery

Origin

Qingdao, China

HS Code

8477209000

Production Capacity

20sets\Year

Product Description

PVC ASA composite glazed House roofing tile extrusion line.

PVC Resin Roofing tiles extruding machine.

PVC bamboo tile production line.

720mm/880mm/960mm/1040mm/1050mm

1. PVC glazed roof tile extrusion production line advantages:

high production efficiency, the structure is reasonable and compact, easy operation and maintenance.

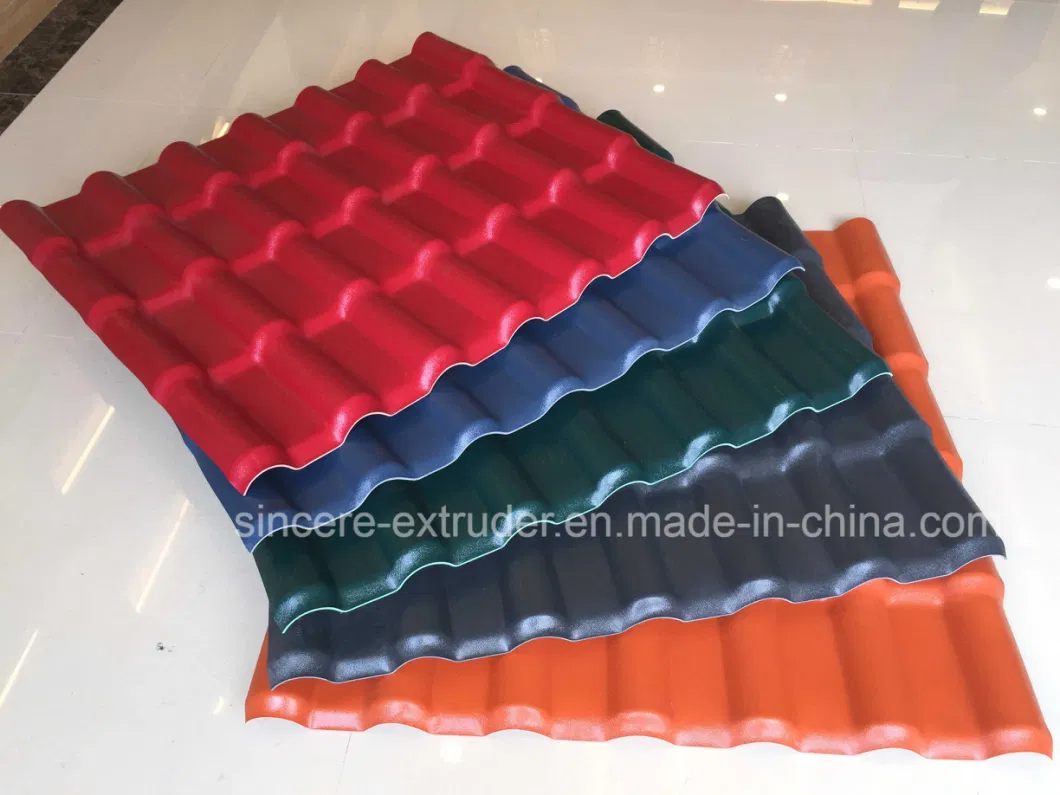

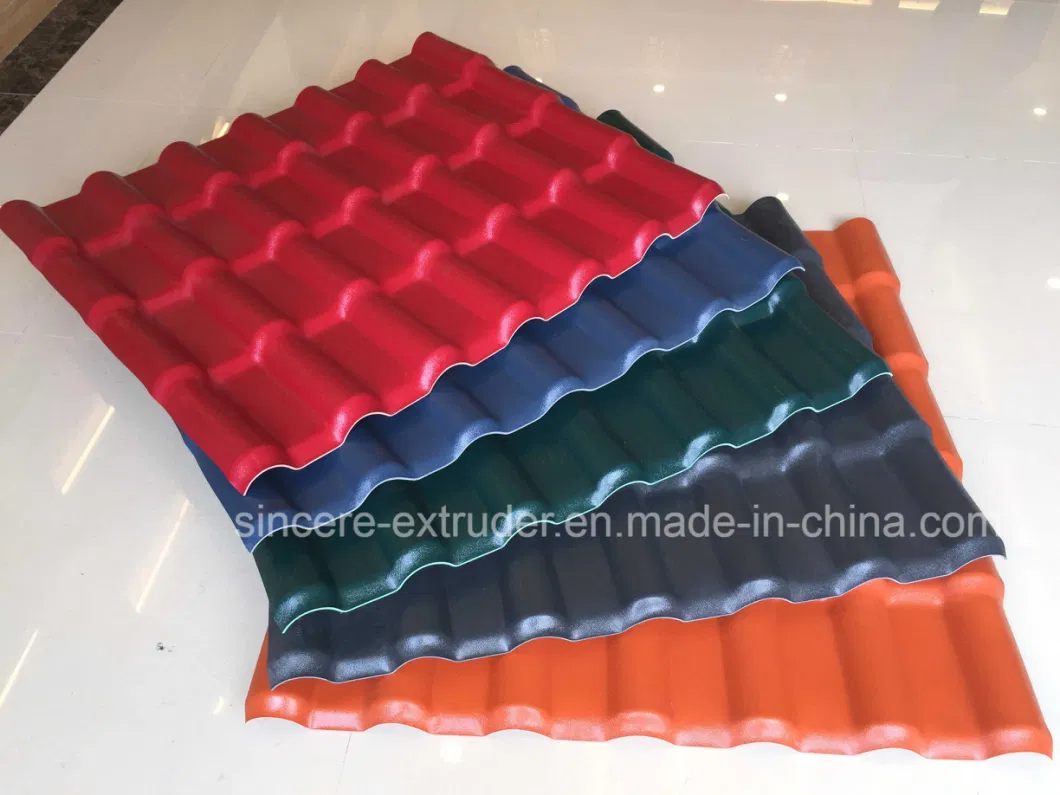

PVC glazed roof tile is widely used in pavilions, hotels, exhibition halls, resorts, families and other buildings. PVC glazed roof tile has a series of advantages: Weather resistance, Corrosion resistant performance, excellent load capacity, Shock resistant and low temperature resistant, Self clean and so on.

2. PVC glazed roof tile extrusion line configuration

Auxiliary machine:

3. Main Technical Specifications:

4. Raw material & Final product of ROOF TILE MAKING MACHINE:

5. Work condition (provide by customer) of ROOF TILE MAKING MACHINE:

6. Energy consumption of ROOF TILE MAKING MACHINE:

7. Main commercial terms of ROOF TILE MAKING MACHINE:

Contacts:

Ekaterina

Mob.+8615726275773

PVC Resin Roofing tiles extruding machine.

PVC bamboo tile production line.

720mm/880mm/960mm/1040mm/1050mm

1. PVC glazed roof tile extrusion production line advantages:

high production efficiency, the structure is reasonable and compact, easy operation and maintenance.

PVC glazed roof tile is widely used in pavilions, hotels, exhibition halls, resorts, families and other buildings. PVC glazed roof tile has a series of advantages: Weather resistance, Corrosion resistant performance, excellent load capacity, Shock resistant and low temperature resistant, Self clean and so on.

2. PVC glazed roof tile extrusion line configuration

| No | Name | Number |

| 1 | Screw loader for SJZ80/156 | 1set |

| 2 | SJZ80/156 Conical twin screw extruder | 1set |

| 3 | drying hopper for SJ50/30 | 1set |

| 4 | Vacuum loader for SJ50/30 | 1set |

| 5 | SJ50/30 single screw extruder | 1set |

| 6 | Extrusion Mould and Distributor (T-die) | 1set |

| 7 | DistributorForming machine | 1set |

| 8 | Embossing roller Trimming device | 1set |

| 9 | Embossing roller | 1set |

| 10 | Cutter | 1set |

| 11 | Stacker | 1set |

Auxiliary machine:

| No | Name | Number |

| 1 | Accessories machines for Top Ridge (Europe Style Tile), Side ridge, three way ridge, End Ridge, fittings. | 1.1)Flat sheet haul-off unit, 1 set 1.2)Oven,1set 1.3)Ridge tile forming unit,1set 1.4)ridge tile mold, 4sets |

| 2 | Mixer 200|500 or 300|600 | 1set |

| 3 | Screw loader | 1set |

| 4 | Crusher | 1set |

| 5 | Pulverizer (milling machine) | 1set |

3. Main Technical Specifications:

| Extruder | SJZS-80/156 | SJ50/30 |

| Productivity | 350kg/h | 50kg/h |

| Haul-off power | 20KN | |

| Haul-off speed | 0.3~5m/min | |

| Product specifications (Can be produced according to customer requirements) | Width title:720/880/960/1040mm Pitch:160mm wave length:220mm wave height:30mm Thickness:1~3mm Materials:PVC,ASA or PMMA with different colors and some additives. | |

4. Raw material & Final product of ROOF TILE MAKING MACHINE:

| Raw material & formulation | PVC resin, Caco3, lubricant,stabilizing agent, pigment, anti-ultraviolet agent,Pigment etc |

| Central height: | 1000mm |

| Max. Haul-off speed: | 3m/min |

| Operation direction | From right to left (face to the operation panel) |

| Machine color | Standard color: RAL7016 (Anthracite grey) ; RAL9002 (Grey white) |

| Description final product & Output capacity | Singlelayers PVC Roofing tile; Width:500-1500mm,Thickness: 1.2~3.0mm; Wave distance:180mm; Wave height:30mm; Output:300-400kg/h(Depending on CaCO3 proportion) |

5. Work condition (provide by customer) of ROOF TILE MAKING MACHINE:

| Warehouse/Workshop | Construction of foundations, construction works, earthworks, and wall works; Supply of cranes, fork-lifts or other lifting equipment; Mounting materials and tools; Dimension (M×M×M): 20 (Length)×2.0 (width) ×2.5 (Height) Crane: Machine positioning |

| Temperature & Humidity | ≤40°C, ≤95% |

| Power supply | Supply voltage: 3*380V+N+PE; Voltage tolerance: +5%/-5%; Control voltage: 24VDC+220VAC; Frequency: 50HZ+-2% |

| Wire/cables/water hose: | Wires/cables: from power supply to control cabinet of this production line and all electrical cables from control cabinet to each machine; Water hose: supply water to machines and pools; |

| Cooling Water | Without dissolved or suspended minerals as phosphor, sulphur, iron, etc. Inflow temperature T1: max. 15°C; Outflow temperature T2: T2=T1+5°C; Hardness: 5-8 OdH; Reflux: without pressure |

| Lubrication oil: | Sinopec, Exxon mobile |

| Compressor | Unnecessary |

6. Energy consumption of ROOF TILE MAKING MACHINE:

| Installation power | 135KW,the real consumption only 80% |

| Cooling Water | ≤20°C, ≥0.3Mpa, ~4-5tons/hr |

| Compressedair | 0.3m3/min, >0.6Mpa |

| Manpower | 2-3 Person |

7. Main commercial terms of ROOF TILE MAKING MACHINE:

| Project | PVC roofing tile extrusion line |

| Payment term | 30% as down payment by T/T; 70% by T/T before delivery and after inspection |

| Delivery time | 70 days since the date of receiving down payment |

| Packing | Wood pallet covered by plastic film |

| Warranty period | 12 months since date of bill of lading |

Contacts:

Ekaterina

Mob.+8615726275773