Basic Info.

Model NO.

tiga-2069

Special Use

High-strength Steel Plate

Stock

Stock

Materials

Gl, PPGI, PPGL

Thickness

0.13mm-1.5mm

Tolerance

+/-0.02mm

Normal Size

665, 840, 900, 912, 1050 etc.

Length

as Customer Required

Usage

Roof or Wall

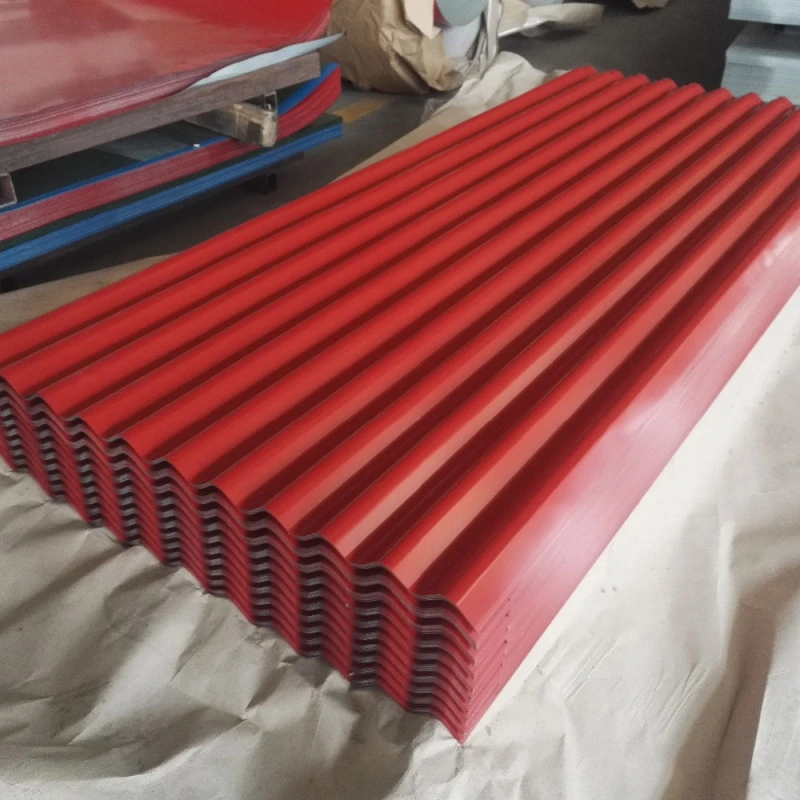

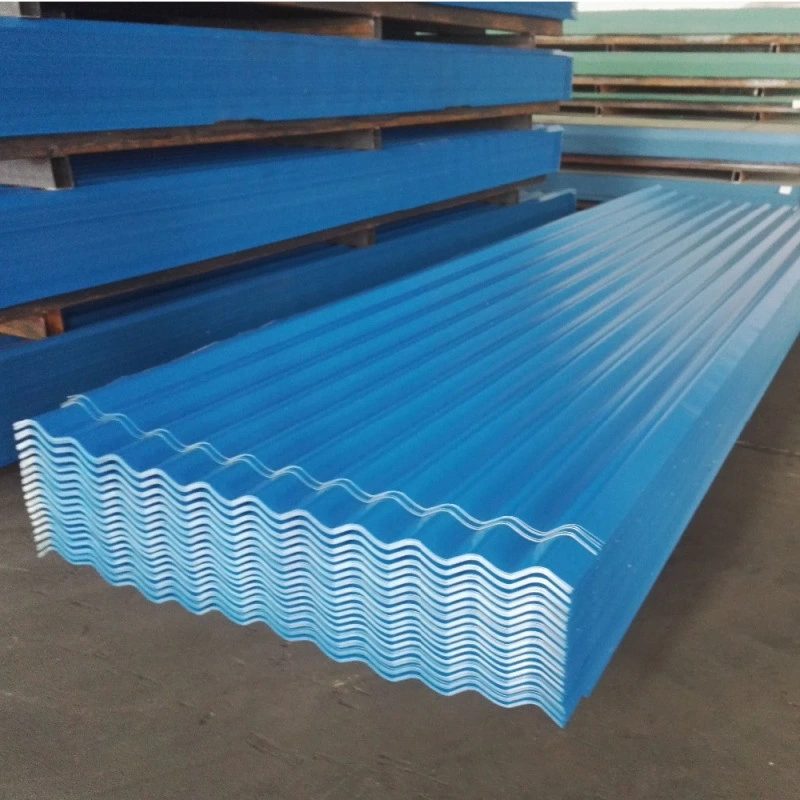

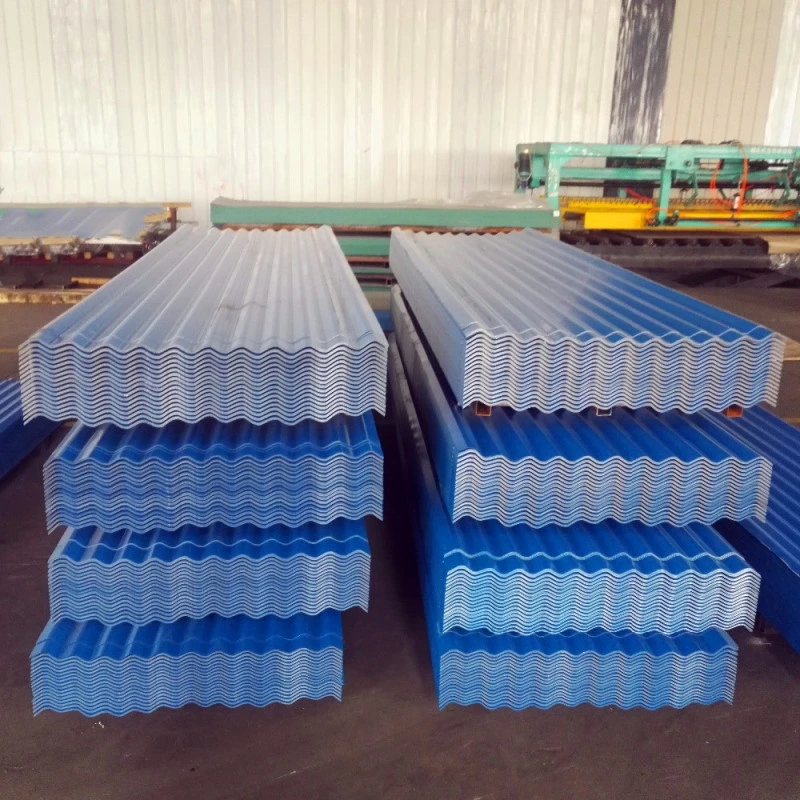

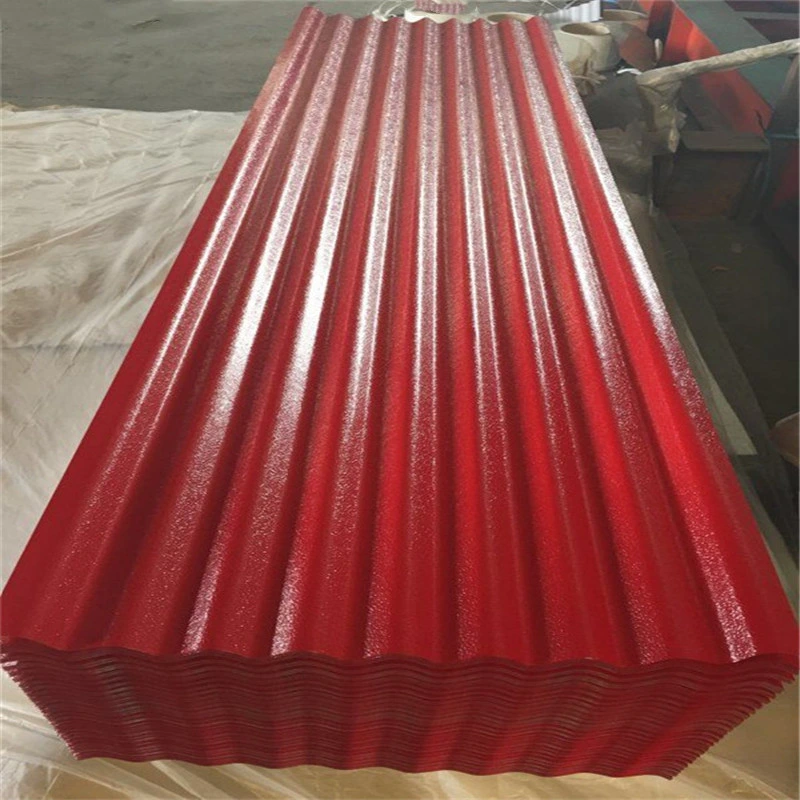

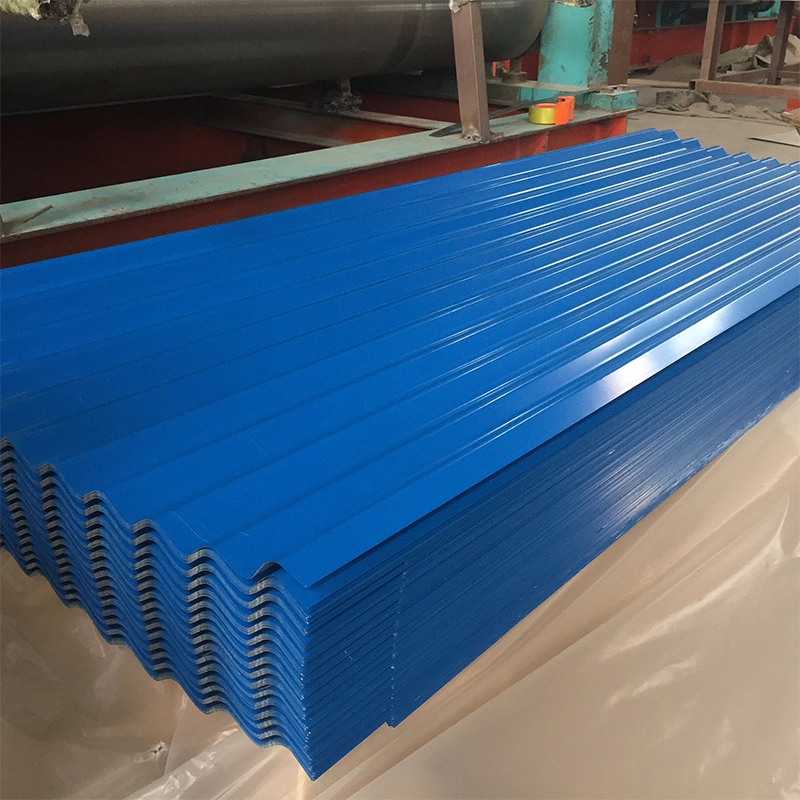

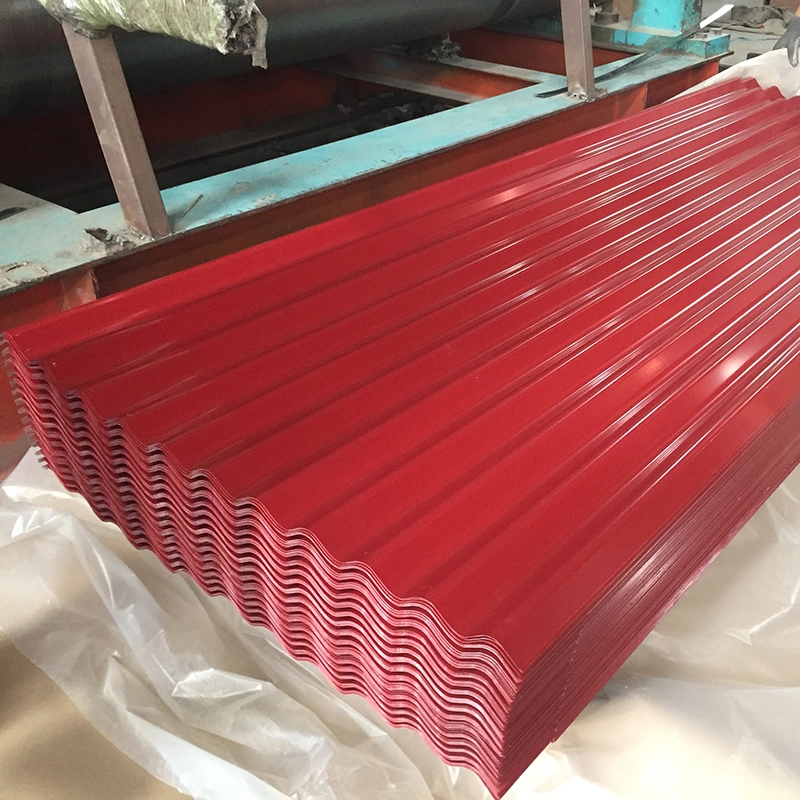

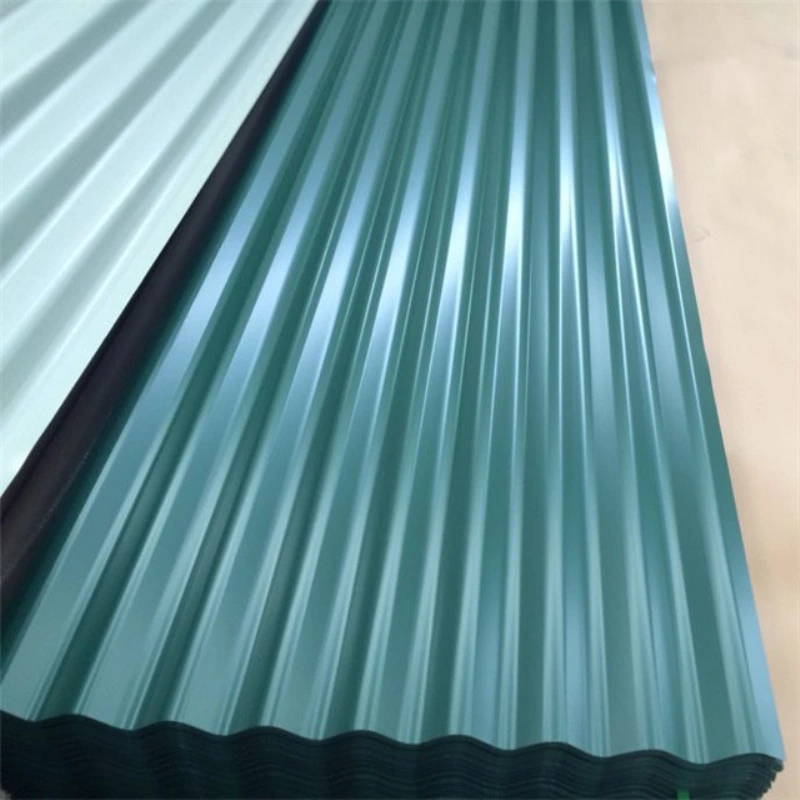

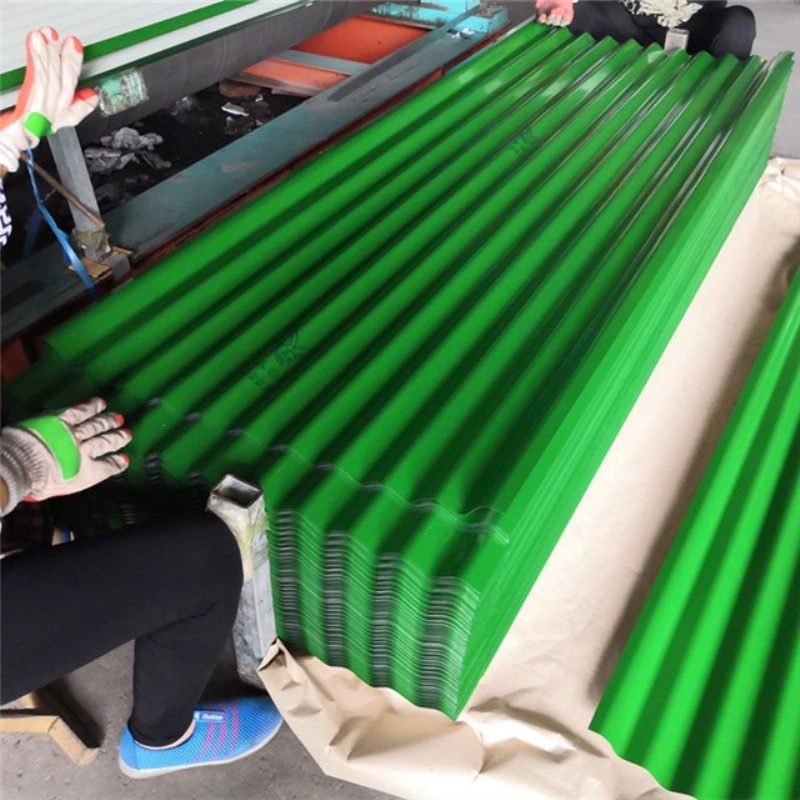

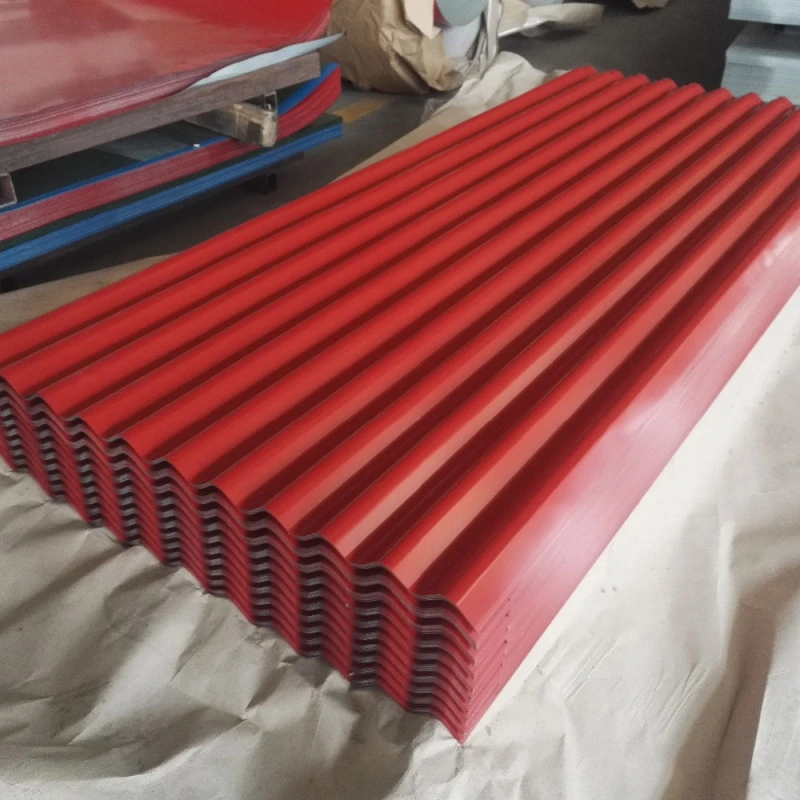

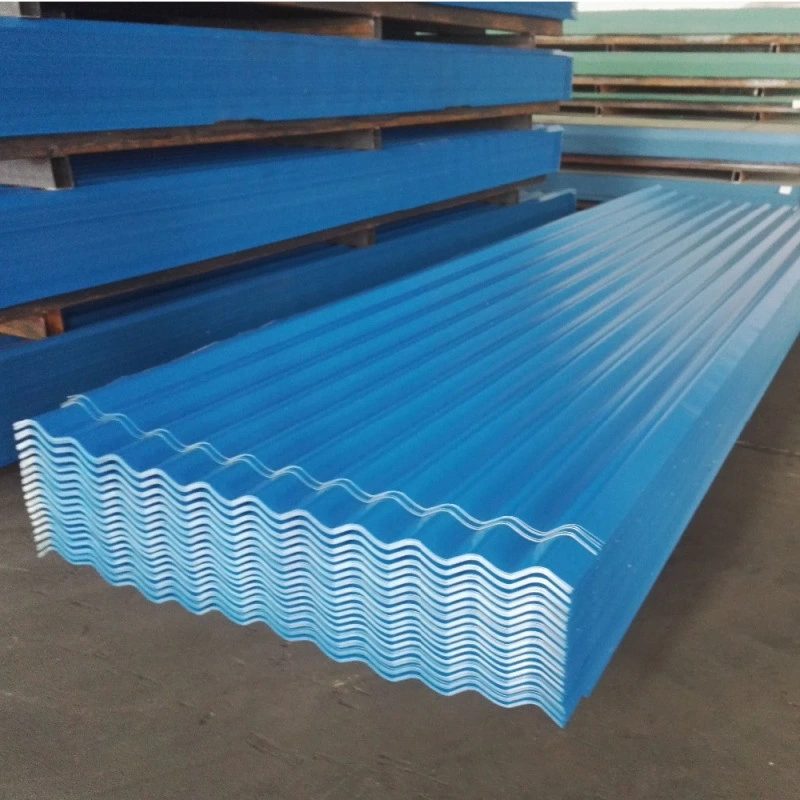

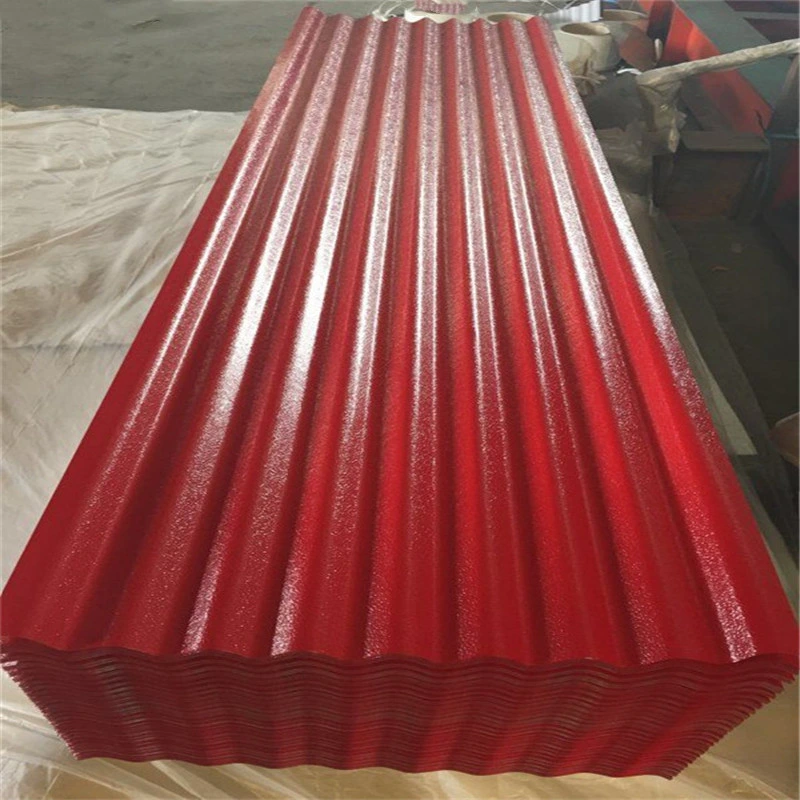

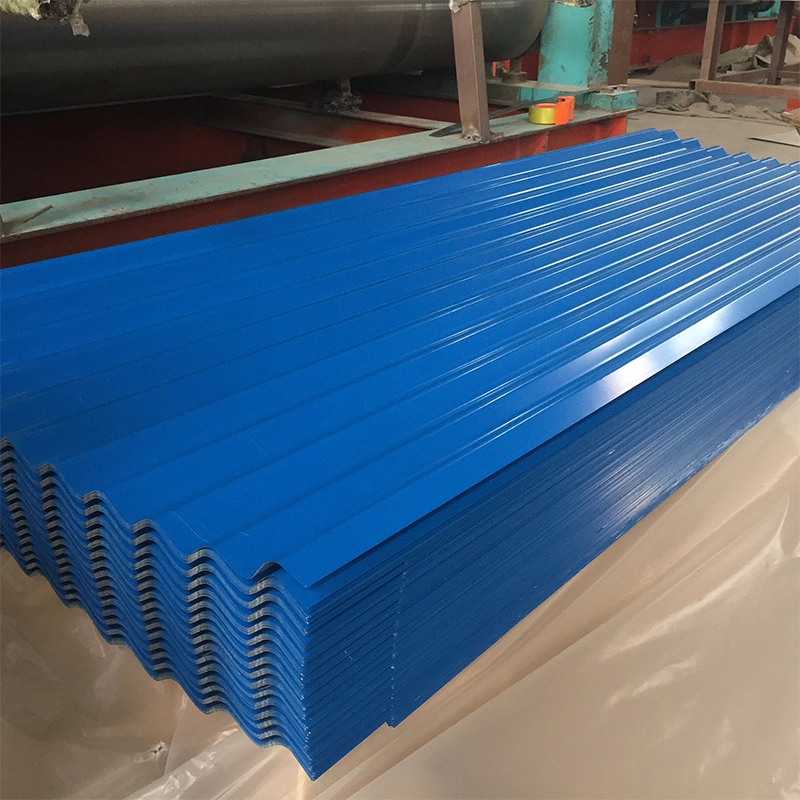

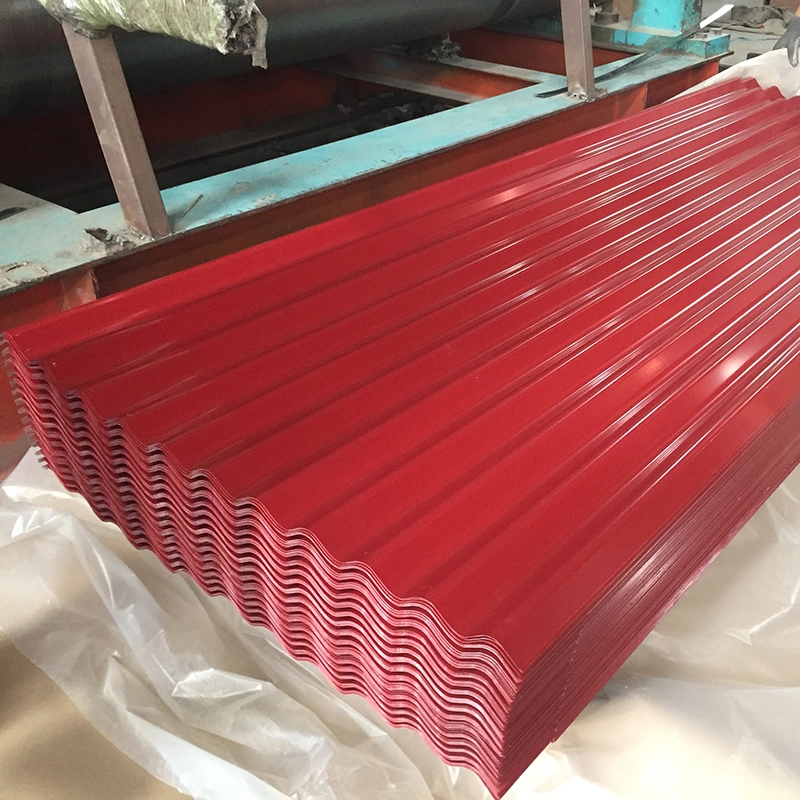

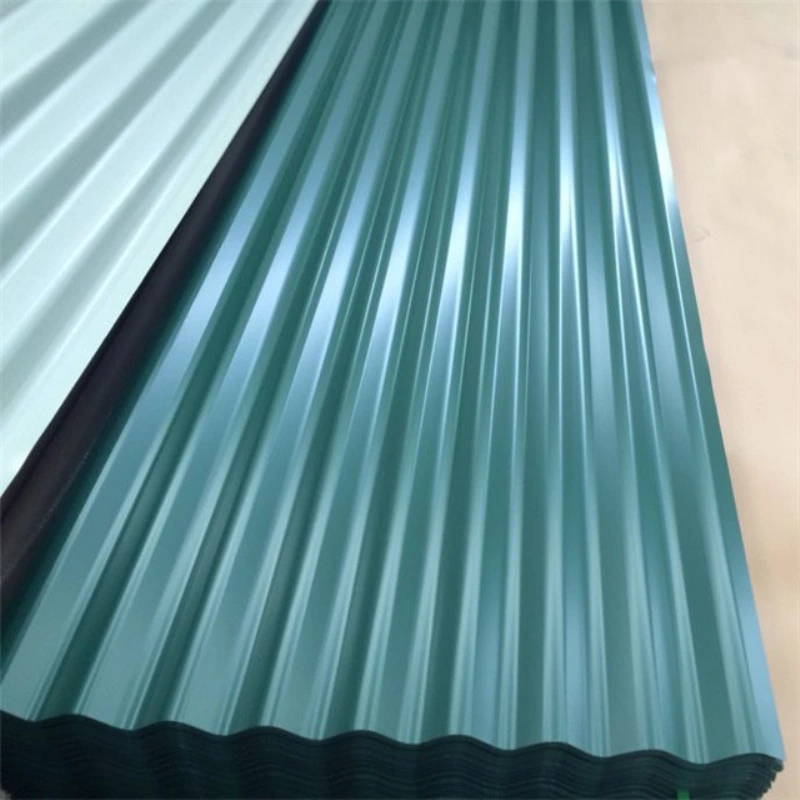

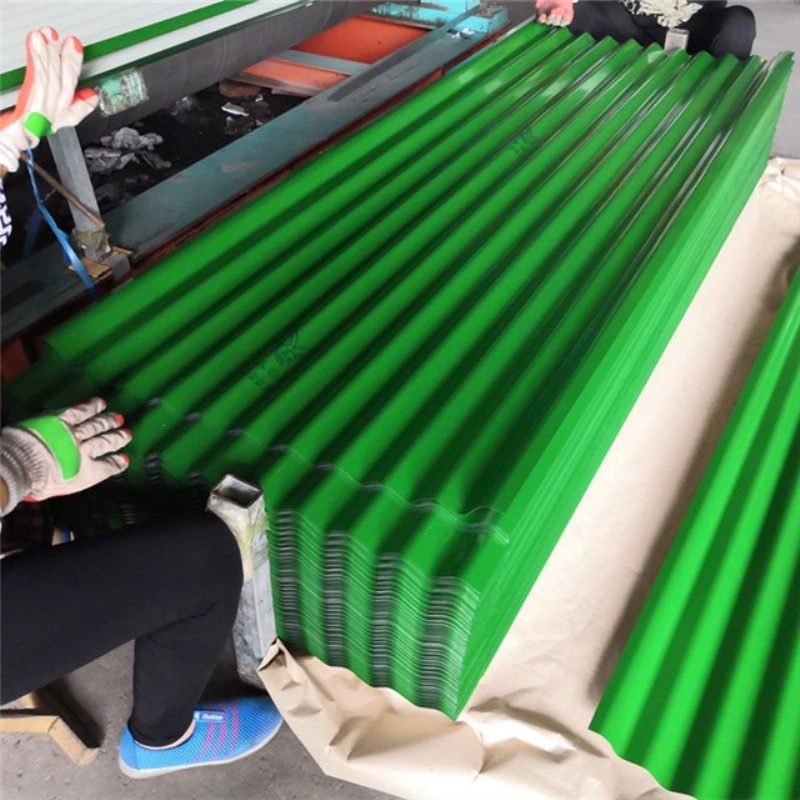

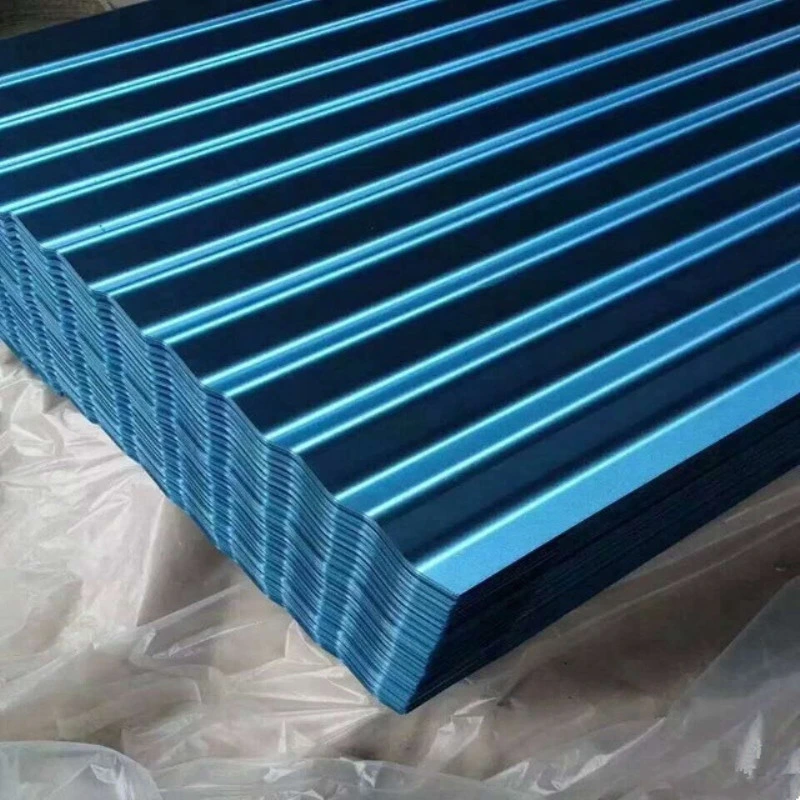

Color

Ral Colors or as The Sample

Coating Structure

2/1 or 2/2

Top Coating

18-35um

Back Coating

7-25um

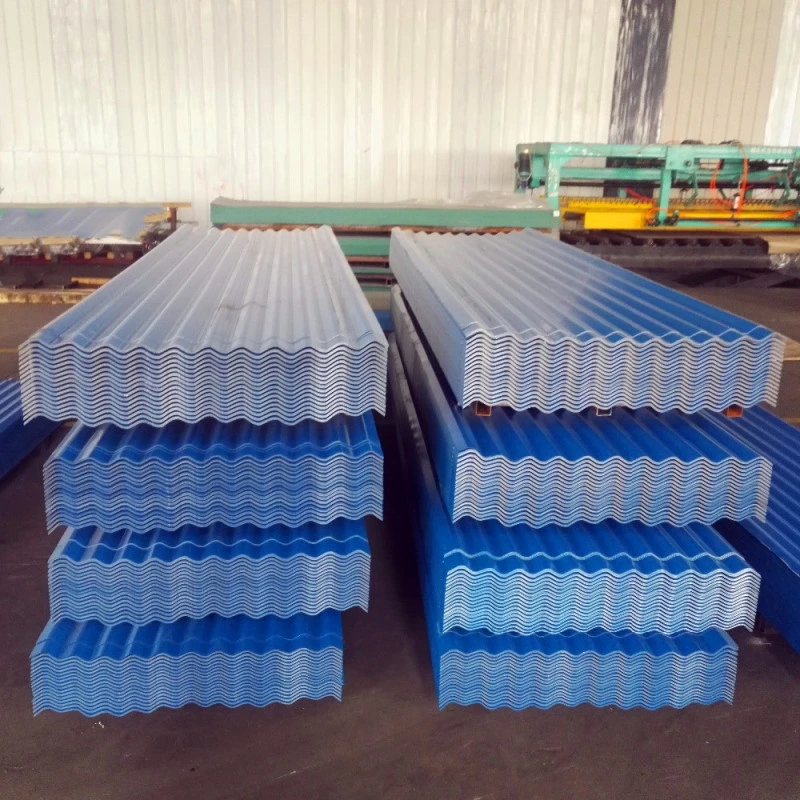

Transport Package

Seaworthy Packaging or as Required

Specification

665, 840, 900, 912, 1050 etc.

Trademark

TIGA

Origin

Henan China

HS Code

72107010

Production Capacity

10000 Tons Per Month

Product Description

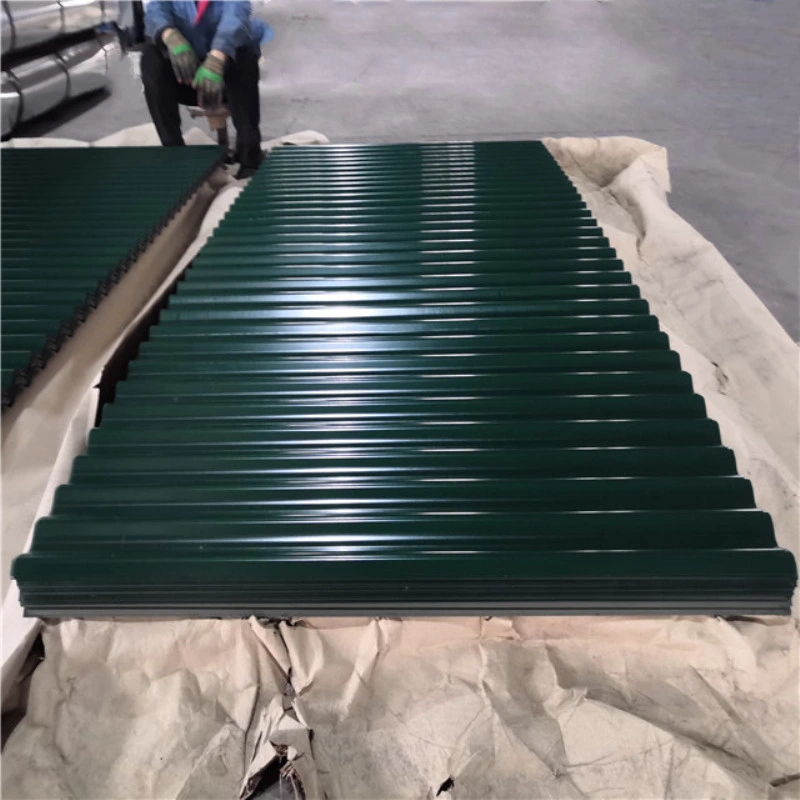

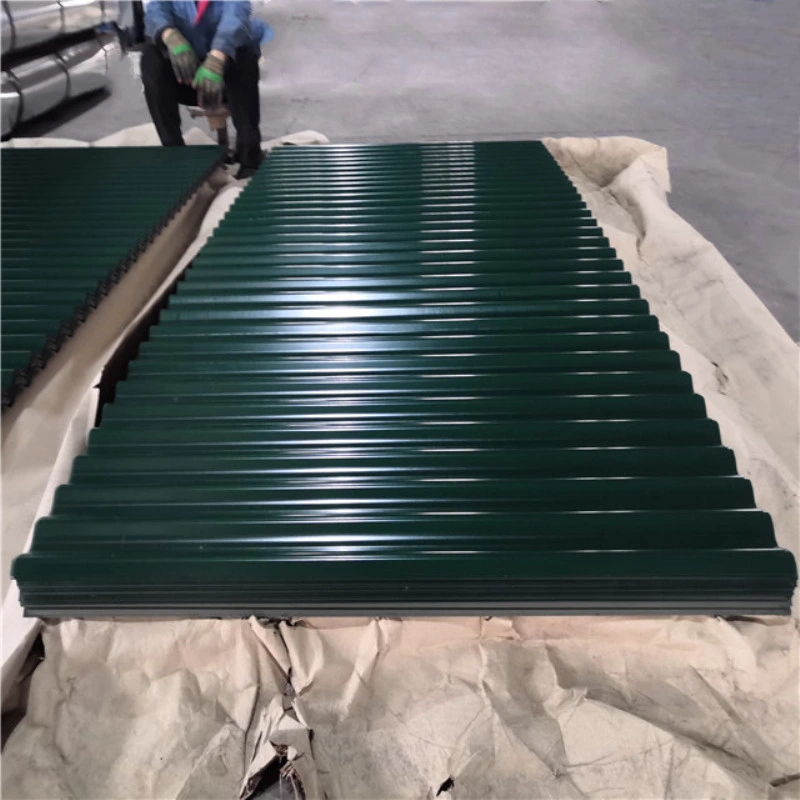

1. Prepainted Galvalnized Steel Roof Sheet introduction:

It is one of the most corrosion resistant materials offered in the architectural roofing and siding panel market. It will give you a great product that lasts longer than the traditional galvanized finish. The corrosion resistance of it will make this the ideal product for almost any application, by marrying the lightweight aspect and advantage of zinc coating and the paint, with less chance of the material corroding at the normal stress points, and areas where rusting can start.

2. Prepainted Galvalnized Steel Roof Sheet main structure:

It is carbon steel sheet coated with zinc coating and paint by a continuous hot-dip process described in Production Methods. Besides, the raw material could also be galvalume steel and prepaited steel (GI,GL,PPGI,PPGL).

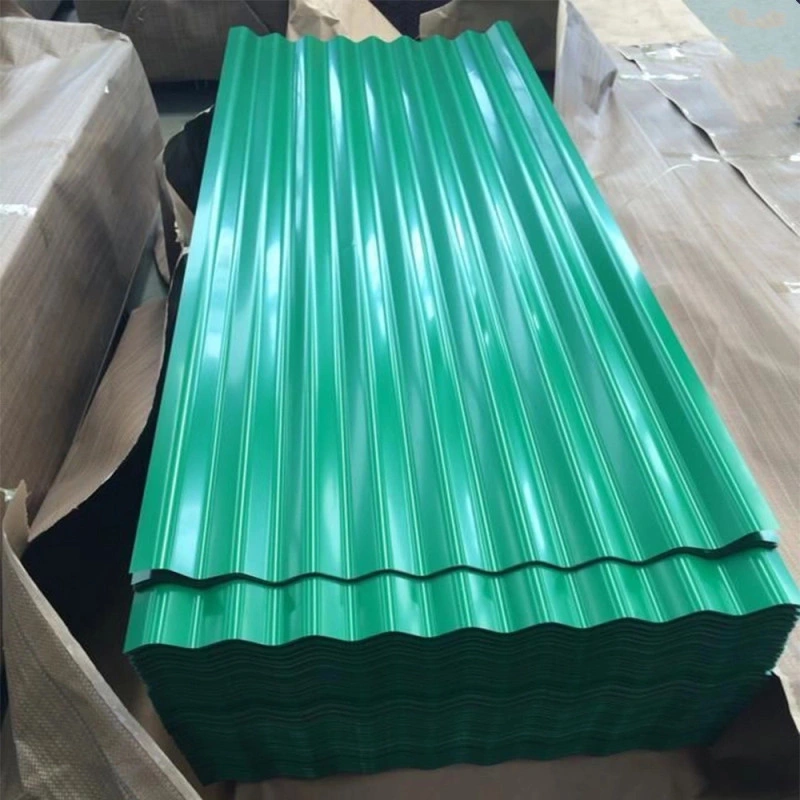

3. Application scope:

It is widely used for commercial, agricultural, and industrial purposes, however, it is now also being recognized as an excellent form of residential roofing. Galvanized steel sheet is also known as sinusoidal, corrugated iron or wriggly tin.

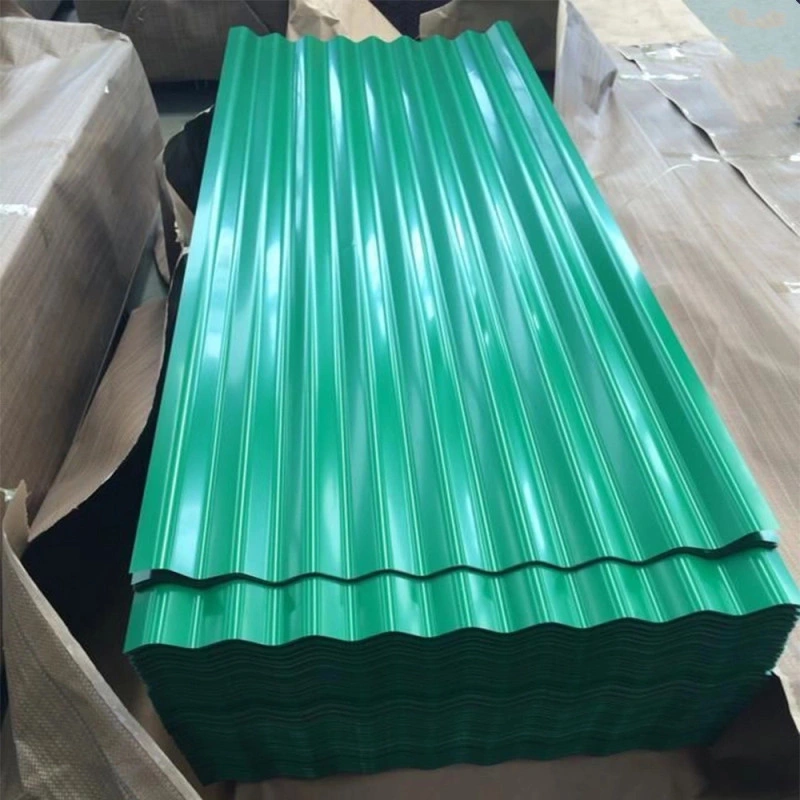

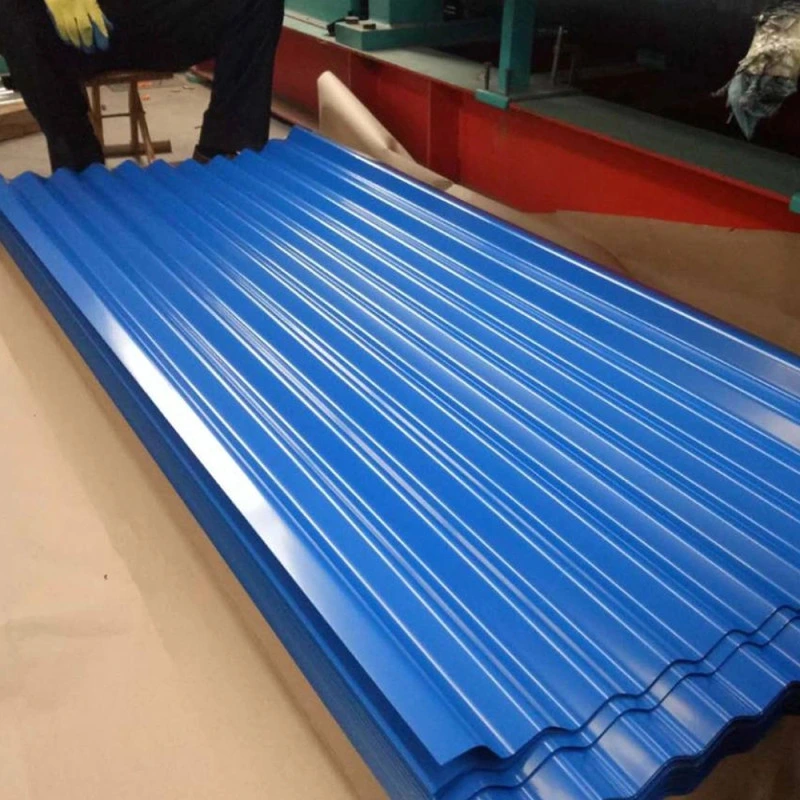

4. Main features:

1)Combine the excellent barrier corrosion protection of aluminum with the galvanic protection of zinc and paint.

2)Preferred product for long-term resistance to atmospheric corrosion

3)The superior corrosion resistance of galvanized steel sheet is achieved by the presence of microscopic zinc-rich and aluminum-rich areas within the coating.

4)Easy to install, high strength and lower costs

5)It is widely used as walls or roofs for factories, warehouses, garages, exhibition centers

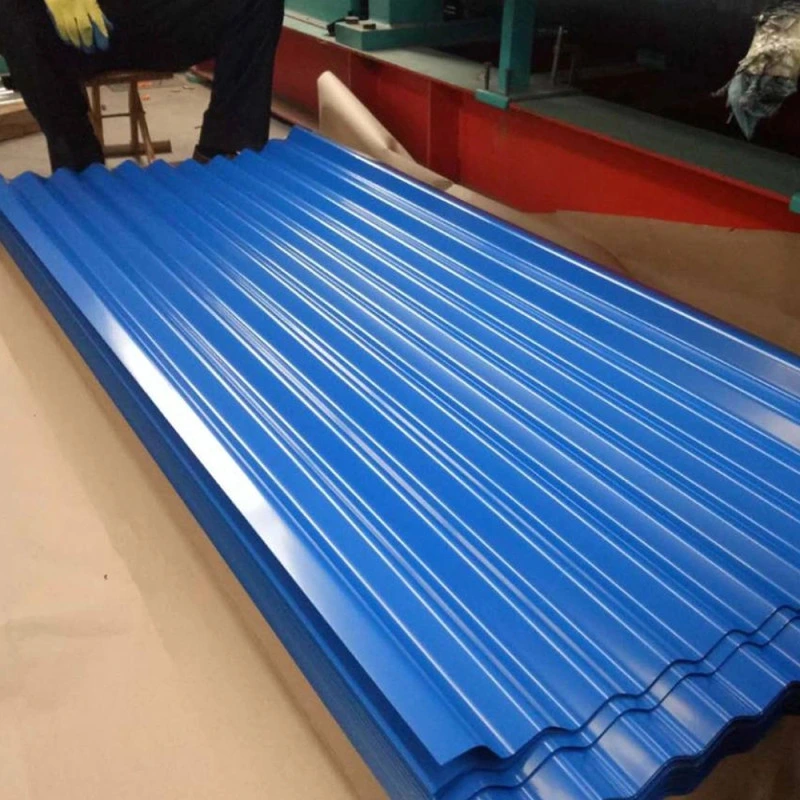

5. Installation tips:

1)Prepare the roof surface by removing any old roofing, rotten wood, and adding roofing felt to the entire surface.

2)Calculate the number of sheets of corrugated metal needed.

3)Place your first metal sheet in a corner of the roof, flush against the surface.

4)Nail in the first metal sheet to the wood of the roof. You should use about 20 nails per sheet.

5)Place the second metal sheet alongside the first with an overlap of 3 to 4 inches (10 cm).

6)Nail the second metal sheet to the roof.

7)Continue with the other sheets, overlapping on every side of each sheet except for at the edges of the roof.

8)Secure ridge caps to the bottom lip of the roof.

9)Test roof for any loose spots or places where water can seep in.

Why Choose US?

1. Advantages: Mill/factory supply,Quality protection,3 steel production lines keep runing for the raw material.

2.Transport&Loading Advantages:We have own Logistic Company, it's the first agent of MSK, MSC, CMA, YML and so on. We also have specifical reforcement team, can save time and money for you.

3.More than 15 years Export Experiences,More than 40 countries customers.

4.Competitive price with best quality and service.Our serviceincludes Small MOQ,Large supply ability,Can accept any complex inquiries,Stock available,Strong processing and warehousing service,Strict quality control,Professional negotiation etc.

5.Delivery time: Within 25-35 days after the deposit.

6.Quality control:Mill Test Certificate is supplied with shipment;Third party inspection is highly welcomed.

It is one of the most corrosion resistant materials offered in the architectural roofing and siding panel market. It will give you a great product that lasts longer than the traditional galvanized finish. The corrosion resistance of it will make this the ideal product for almost any application, by marrying the lightweight aspect and advantage of zinc coating and the paint, with less chance of the material corroding at the normal stress points, and areas where rusting can start.

2. Prepainted Galvalnized Steel Roof Sheet main structure:

It is carbon steel sheet coated with zinc coating and paint by a continuous hot-dip process described in Production Methods. Besides, the raw material could also be galvalume steel and prepaited steel (GI,GL,PPGI,PPGL).

3. Application scope:

It is widely used for commercial, agricultural, and industrial purposes, however, it is now also being recognized as an excellent form of residential roofing. Galvanized steel sheet is also known as sinusoidal, corrugated iron or wriggly tin.

4. Main features:

1)Combine the excellent barrier corrosion protection of aluminum with the galvanic protection of zinc and paint.

2)Preferred product for long-term resistance to atmospheric corrosion

3)The superior corrosion resistance of galvanized steel sheet is achieved by the presence of microscopic zinc-rich and aluminum-rich areas within the coating.

4)Easy to install, high strength and lower costs

5)It is widely used as walls or roofs for factories, warehouses, garages, exhibition centers

5. Installation tips:

1)Prepare the roof surface by removing any old roofing, rotten wood, and adding roofing felt to the entire surface.

2)Calculate the number of sheets of corrugated metal needed.

3)Place your first metal sheet in a corner of the roof, flush against the surface.

4)Nail in the first metal sheet to the wood of the roof. You should use about 20 nails per sheet.

5)Place the second metal sheet alongside the first with an overlap of 3 to 4 inches (10 cm).

6)Nail the second metal sheet to the roof.

7)Continue with the other sheets, overlapping on every side of each sheet except for at the edges of the roof.

8)Secure ridge caps to the bottom lip of the roof.

9)Test roof for any loose spots or places where water can seep in.

Why Choose US?

1. Advantages: Mill/factory supply,Quality protection,3 steel production lines keep runing for the raw material.

2.Transport&Loading Advantages:We have own Logistic Company, it's the first agent of MSK, MSC, CMA, YML and so on. We also have specifical reforcement team, can save time and money for you.

3.More than 15 years Export Experiences,More than 40 countries customers.

4.Competitive price with best quality and service.Our serviceincludes Small MOQ,Large supply ability,Can accept any complex inquiries,Stock available,Strong processing and warehousing service,Strict quality control,Professional negotiation etc.

5.Delivery time: Within 25-35 days after the deposit.

6.Quality control:Mill Test Certificate is supplied with shipment;Third party inspection is highly welcomed.

| Standard | ASTM A653, JIS G3302,GB/T3830-2006 |

| Grade | DX51D,SGCC,SPCC,SGHC |

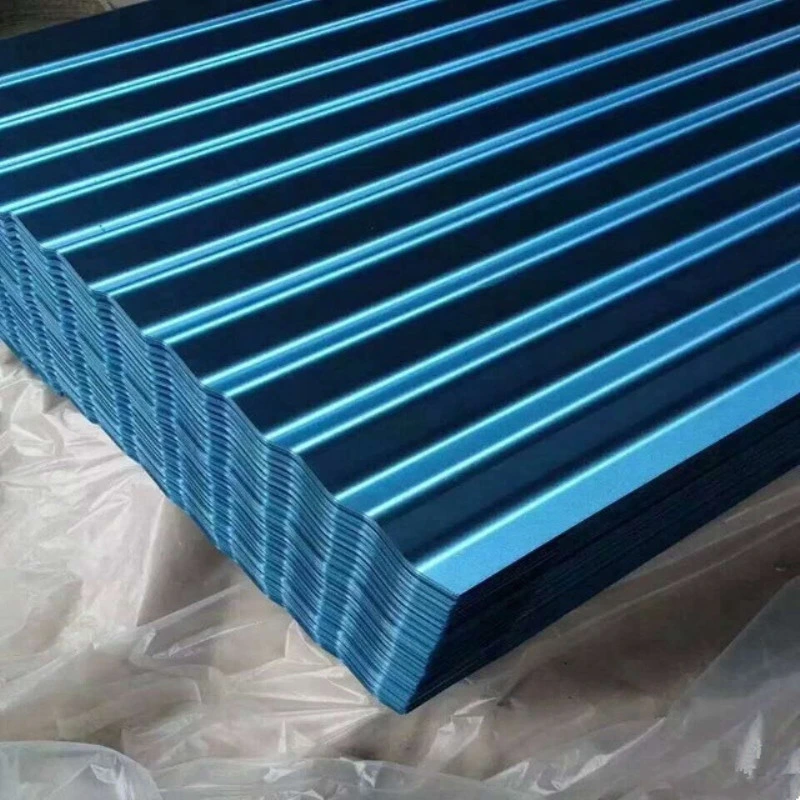

| Thickness | 0.14mm--1.2mm |

| Width | 665mm 680mm 750mm 820mm 840mm 860mm 1020mm 1025mm 1050mm |

| Raw materials | Galvanized steel,Galvalume steel, Galvalume Pre-painted sheet and aluminium sheet |

| Steel grade | Q195,Q235,Q235B,Q215,DX51D,SPCC,SGCC |

| Base metal | Galvanized steel sheet |

| Hardness | Soft to full hard etc. |

| Zinc coating | 40-275g/sqm |

| surface structure | Galvanized,Zero Spangle,Regular spangle or normal spangle |

| Surface Treatment | Chromated and oiled, chromated and non-oiled |

| Lenght | 1830 2440 3660mm or customized |

| Coating thickness | Top:10-25um back:7-10um |

| Color options | Ral number or as per your request |

| Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

| Delivery | Within 10-15days after signing contract |

| Price | FOB&CNF&CIF price |

| Payment terms | TT or L/C |

| Monthly supply | 30000MT per month |

| Application: | workshop, storeroom, wall, roofing, fencing |