Product Description

Company Introduction

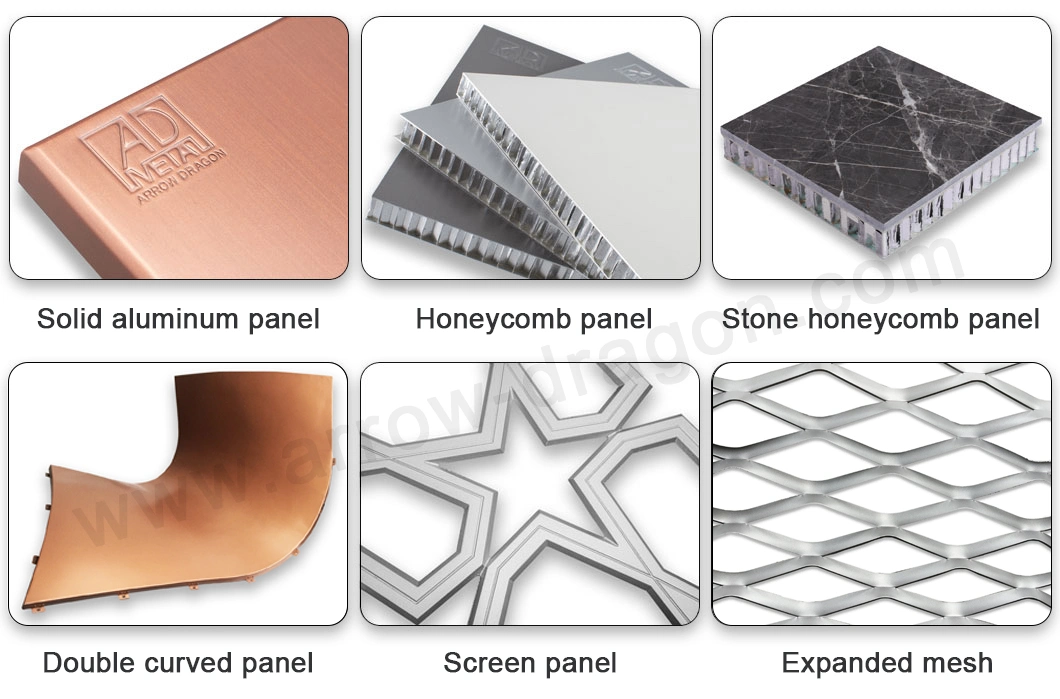

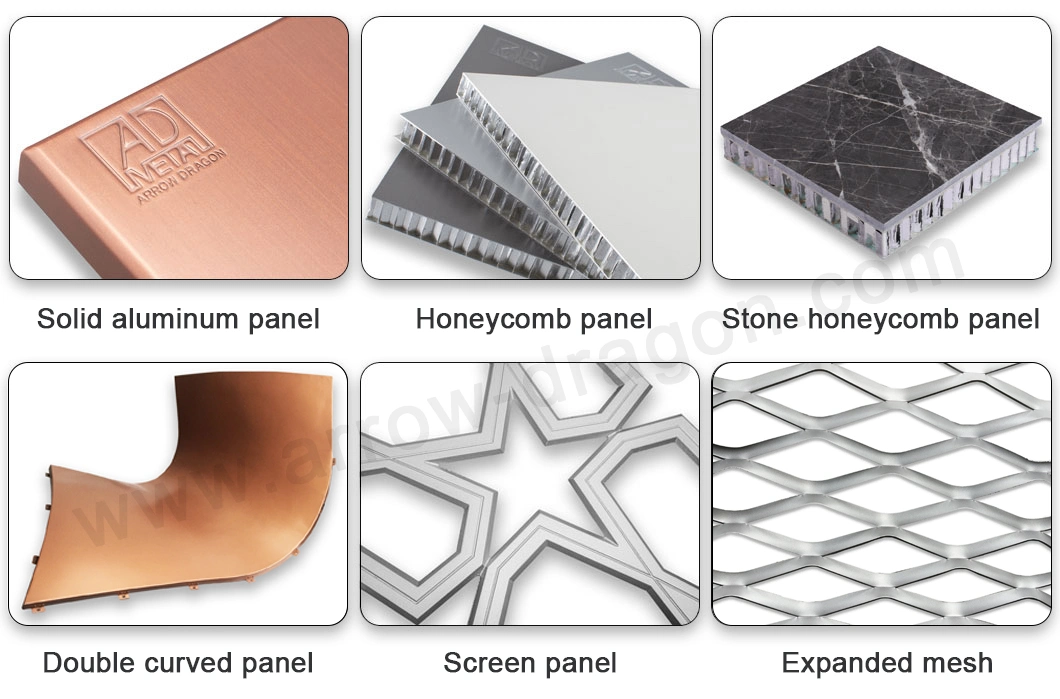

Arrow Dragon Metal Products Co., Ltd specializes in aluminum panels, including regular wall panels (solid aluminum panels, perforated/laser cut panels), curved panels (single curved/double curved/twisted panels), honeycomb panels (aluminum/stone aluminum honeycomb panels), expanded mesh, screen panels, and honeycomb core (aluminum/s.s./mild steel honeycomb core). Due to our outstanding metalwork and stable coating quality, our products have been approved by architects and used in many big projects (pls find it in below Projects Reference).

Solid aluminum wall panels are made of high-quality aluminum plates, and apply PVDF/powder coating on the surface, the panels can be prevented color fading and corrosion from UV, high temperature, humidity, and atmospheric erosion.

Our 6 Main Products

Specification of Solid Aluminum Wall Panel

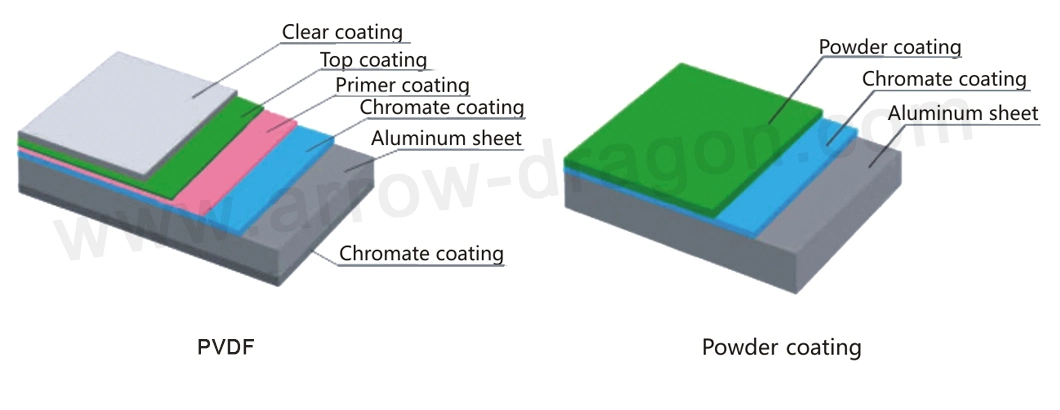

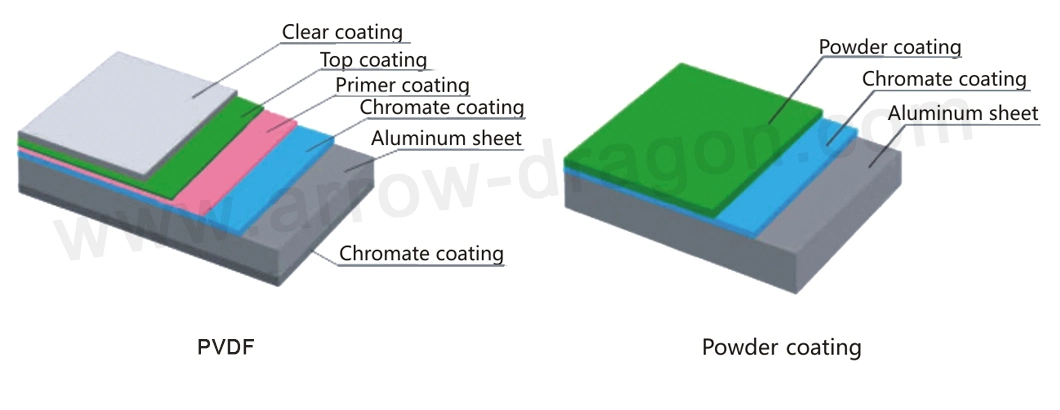

Coating layer composition of PVDF and powder coating

Regular Patterns of Wall Panels

Solid aluminum wall panel: it's widely used in public places, shopping malls, commercial buildings, and office buildings.

Perforated panel/laser-cut panel: it's an ideal option for iconic buildings with the customized patterns which will leave a deep impression at first sight.

Features of Aluminum Wall Panel

Production Procedure

Sheet metal procedure

Cutting/Shearing - Punching - Arcrolling - Bending - Welding - Burnishing - Rib Assembling - Rivet Assembling - Polishing - Spray Coating.

Spray coating procedure

Hanging - Skim - Alkali - Elimination (by acid) - Chromizing - Drying - Spraying (primer coating, top coating, clear coating) - Baking - Inspection.

Quality Control

Chromatic aberration test: with the colorimeter to ensure the color of mass production panel matches with GB standard.

Glossiness test: gloss is a measure of how reflective material is at a specified angle based on the refractive index.

Coating thickness test: ensure average coating thickness match to KYNAR 500 standard.

Pencil hardness test: coating hardness test.

Hundred grid test: coating adhesion test, will be done before the 3M adhesive tape test.

3M adhesive tape test: after the coating is completely dry, 3M adhesive tape in painting has hundreds grid ink surface, 45 degrees quickly pulled off.

Impact test: coating adhesion test.

Package & Delivery

Inner packing: film + foam

Outer packing: wooden crate, wooden crate + steel strip

Application

Exterior application: wall cladding, façade, soffit, roof, canopy, tunnel, column cover or renovation, walkway roof covering, pedestrian overhead bridge roof covering.

Interior application: wall cladding, column cladding, ceiling.

Advertisement and market applications: display platforms, signboard, fascias, and shop fronts.

It also offers excellent performance on the exterior surfaces of garages, outbuildings, and similar applications where good looks are important and durability is critical.

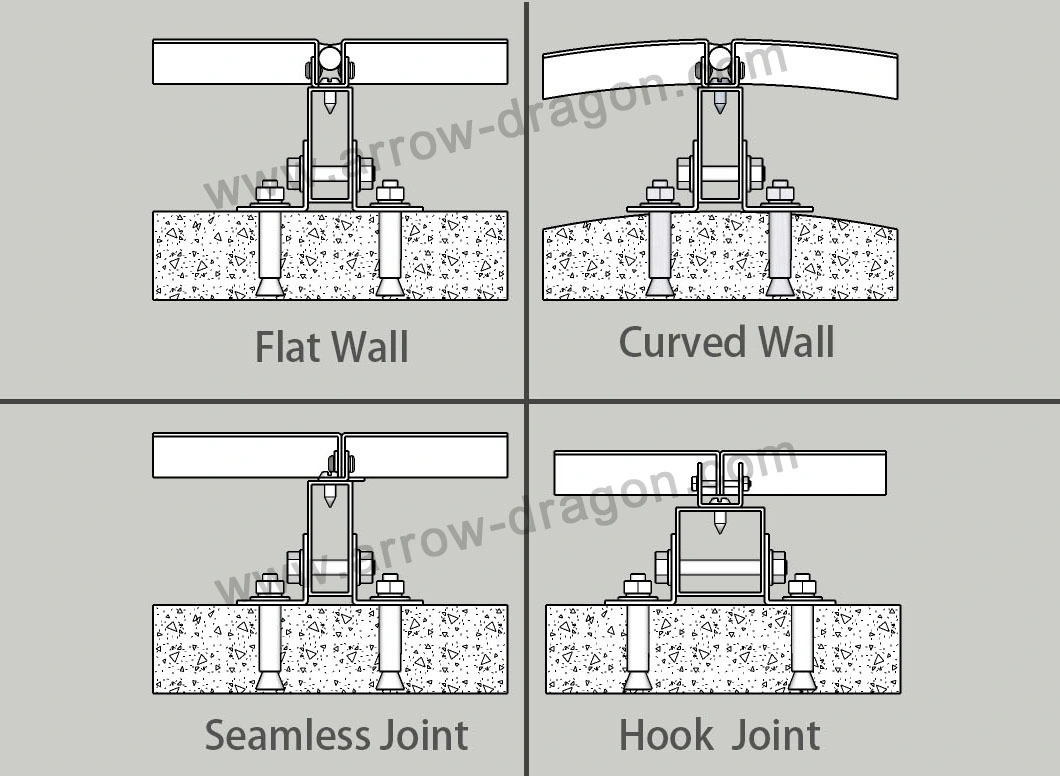

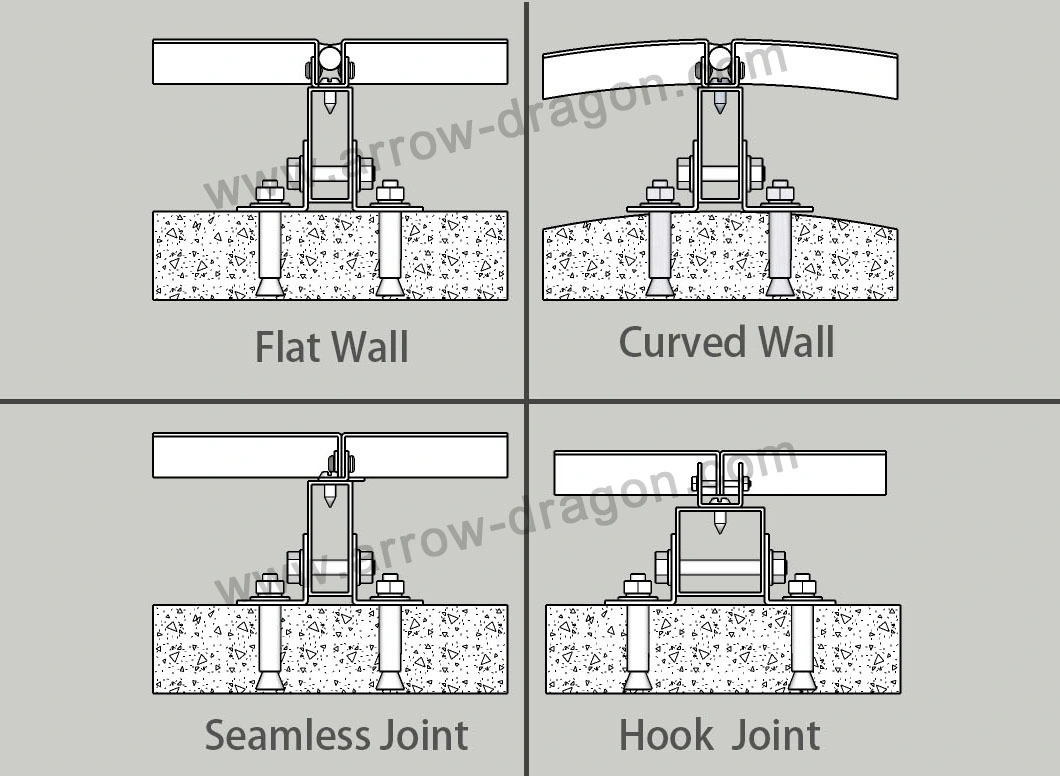

Installation Diagram

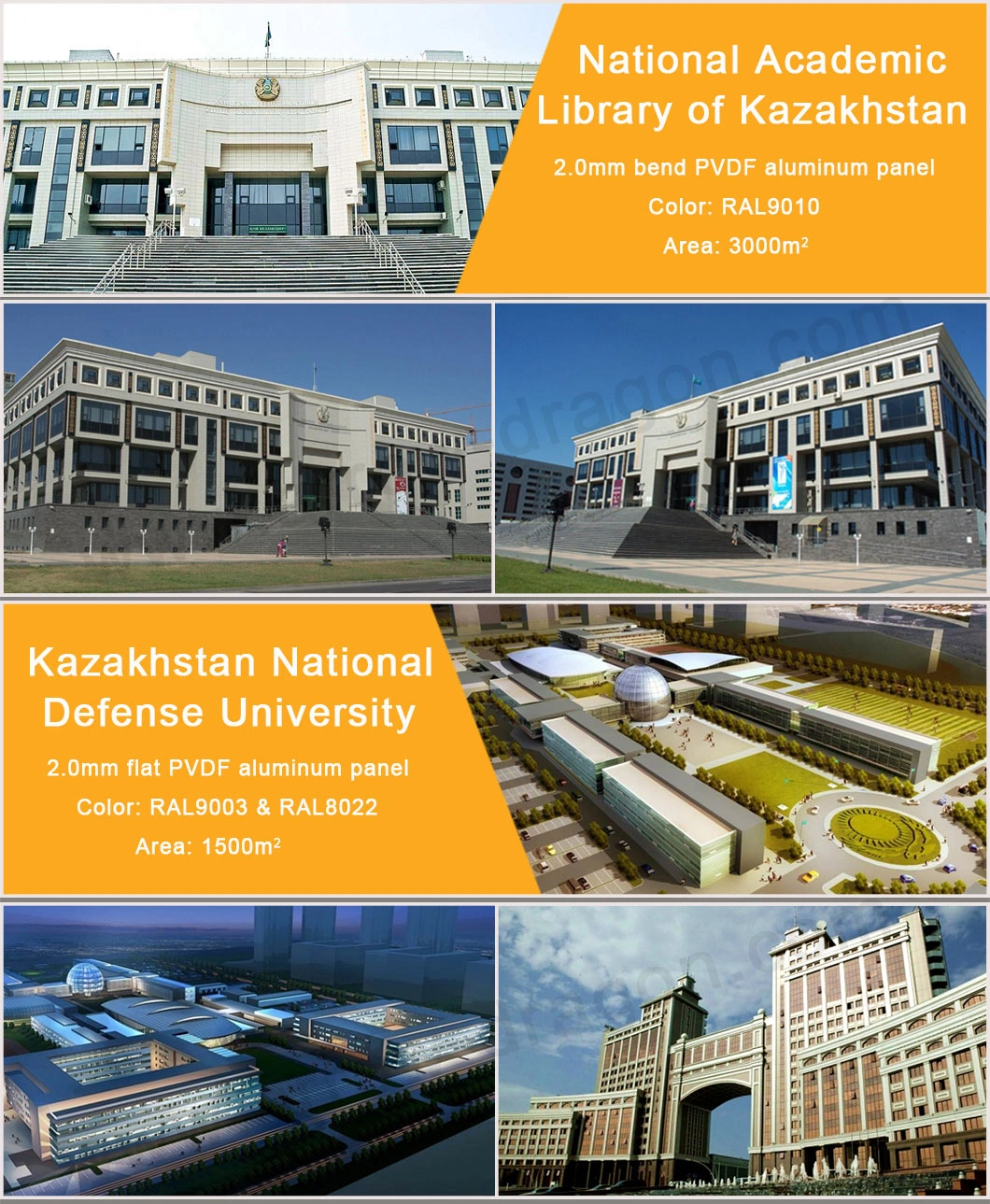

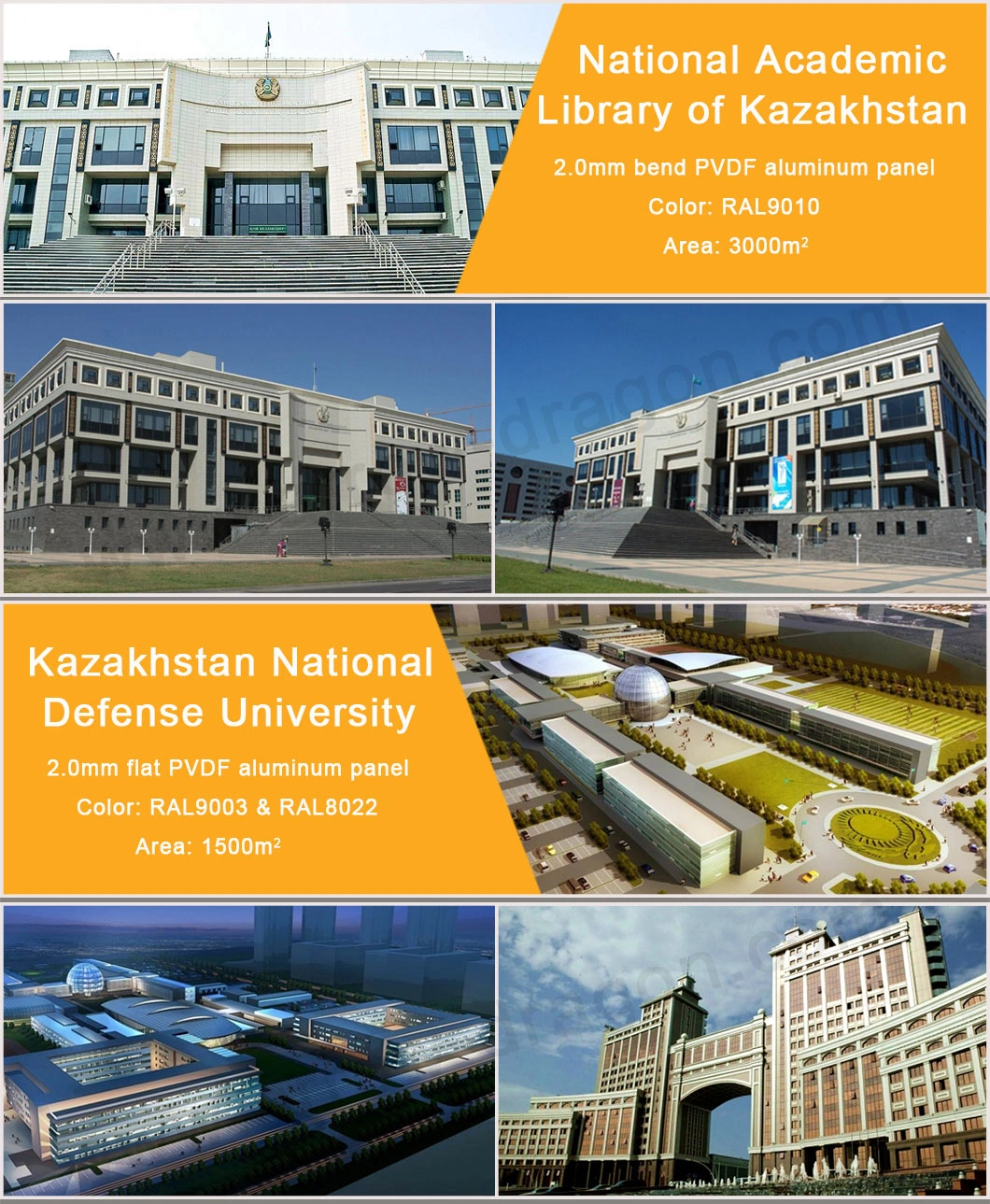

Projects Reference

International Exhibition

FAQ

Arrow Dragon Metal Products Co., Ltd specializes in aluminum panels, including regular wall panels (solid aluminum panels, perforated/laser cut panels), curved panels (single curved/double curved/twisted panels), honeycomb panels (aluminum/stone aluminum honeycomb panels), expanded mesh, screen panels, and honeycomb core (aluminum/s.s./mild steel honeycomb core). Due to our outstanding metalwork and stable coating quality, our products have been approved by architects and used in many big projects (pls find it in below Projects Reference).

Solid aluminum wall panels are made of high-quality aluminum plates, and apply PVDF/powder coating on the surface, the panels can be prevented color fading and corrosion from UV, high temperature, humidity, and atmospheric erosion.

Our 6 Main Products

Specification of Solid Aluminum Wall Panel

| Aluminum alloy | 1100, 3003, 5005, 5052 |

| Panel thickness | 2.0~5.0mm or customized thickness |

| Dimension | Width: up to 2200mm Length: up to 6000mm |

| Surface treatment | PVDF 2/3/4 Layer coating (AkzoNobel/PPG) Powder coating (Powder/fluorocarbon powder) Wood grain (wood grain paper/thermal transfer printing/wood grain painting) Stone grain (stone grain painting/thermal transfer printing) |

| Color | Pure color, metallic color, RAL color, Pantone color |

| Shape | Cambered, bent, single curved, customized shapes |

| Warranty | Max 25 years guarantee for the ideal application environment |

Coating layer composition of PVDF and powder coating

Regular Patterns of Wall Panels

Solid aluminum wall panel: it's widely used in public places, shopping malls, commercial buildings, and office buildings.

Perforated panel/laser-cut panel: it's an ideal option for iconic buildings with the customized patterns which will leave a deep impression at first sight.

Features of Aluminum Wall Panel

- Lightweight, good rigidity, and intensity.

- Good weather ability and good corrosion resistance.

- Can be curved with customized patterns.

- Three-dimensional view to match the building structure.

- Strong Anti-seismic and fireproof performance.

- High resistance to moisture and corrosion.

- Coating uniform, varied color choices.

- Not easy to stain, convenient to clean and maintain.

- Easy for installation and cost-effective.

- Recyclable, friendly to the environment.

Production Procedure

Sheet metal procedure

Cutting/Shearing - Punching - Arcrolling - Bending - Welding - Burnishing - Rib Assembling - Rivet Assembling - Polishing - Spray Coating.

Spray coating procedure

Hanging - Skim - Alkali - Elimination (by acid) - Chromizing - Drying - Spraying (primer coating, top coating, clear coating) - Baking - Inspection.

Quality Control

Chromatic aberration test: with the colorimeter to ensure the color of mass production panel matches with GB standard.

Glossiness test: gloss is a measure of how reflective material is at a specified angle based on the refractive index.

Coating thickness test: ensure average coating thickness match to KYNAR 500 standard.

Pencil hardness test: coating hardness test.

Hundred grid test: coating adhesion test, will be done before the 3M adhesive tape test.

3M adhesive tape test: after the coating is completely dry, 3M adhesive tape in painting has hundreds grid ink surface, 45 degrees quickly pulled off.

Impact test: coating adhesion test.

Package & Delivery

Inner packing: film + foam

Outer packing: wooden crate, wooden crate + steel strip

Application

Exterior application: wall cladding, façade, soffit, roof, canopy, tunnel, column cover or renovation, walkway roof covering, pedestrian overhead bridge roof covering.

Interior application: wall cladding, column cladding, ceiling.

Advertisement and market applications: display platforms, signboard, fascias, and shop fronts.

It also offers excellent performance on the exterior surfaces of garages, outbuildings, and similar applications where good looks are important and durability is critical.

Installation Diagram

Projects Reference

International Exhibition

FAQ