Product Description

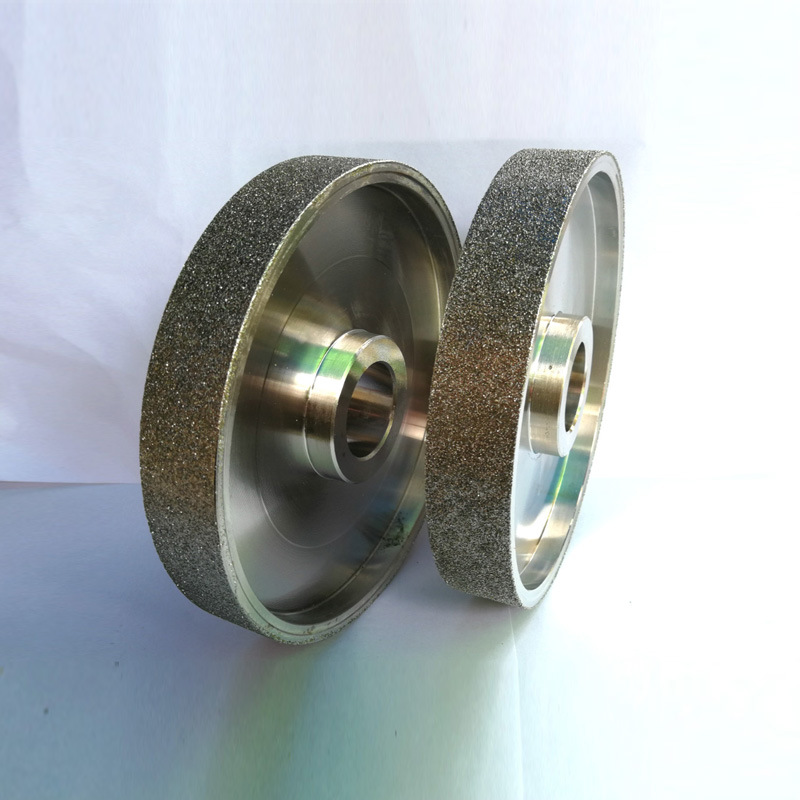

Electroplated Diamond and CBN Grinding Wheel

Electroplated Grinding Wheel is a grinding wheel made by electrochemical method. The grinding wheel working layer contains diamond grinding particles, and the diamond abrasive is bonded to the substrate by a metal bond.Somebetter offers various Diamond /CBN Grinding Wheels, including Resin Bond , Metal Bond and Vitrified Diamond wheels.

Working layer:Diamond/CBN layer.consing of abrasives.binders and filers, it is the working part of the ginding wheel.

Base body:aluminum or steel,the role of supporting the working layer.

Transition layer:consisting of a binding agent, metal powder and fller, the connection of the working layer and the base body.

Advantages:

1)electroplated process is simple, less investment, convenient manufacture;

2)No need to trim, easy to use;

3)monolayer structure determines the it can achieve very high working speed, currently , has been as high as 250 ~ 300m / S;

4)although only a monolayer diamond, but there is still enough life time;

5)for the high precision request rolling wheel, electroplated is the only manufacture method.

Comparison of CBN and Diamond Use:

Due to the different physical and chemical properties of diamond and cubic boron nitride, it is necessary to make appropriate choices based on the workpiece material processed.

Application:

Electropalted Diamond Wheels can be used in many industries, stone polishing, glass polishing polishing. Electroplated CBN wheels can be used in woodworking tool sharpening, HSS Tool sharpening, Carbide Tool Sharpening.

Electroplated Grinding Wheel is a grinding wheel made by electrochemical method. The grinding wheel working layer contains diamond grinding particles, and the diamond abrasive is bonded to the substrate by a metal bond.Somebetter offers various Diamond /CBN Grinding Wheels, including Resin Bond , Metal Bond and Vitrified Diamond wheels.

| Material | Diamond/CBN+metal body(Steel) | Grit size | D46,D54,D64,D76,D91,D107,D126,D151.D180,D213,D251,D301,D356,D426,customized asyour request |

| Diameter | D100,D150,D200,D250,etc | Shape | 1A1,3A1,14A1,1L1,1EE1,1V1,9A3,14U1,1A1R,6A2,11A2,11B2,12B2,11C9,11Y9,6A9,11V9,12V9, 12A2,4A2,1FF1,or drawing as customer's request |

Working layer:Diamond/CBN layer.consing of abrasives.binders and filers, it is the working part of the ginding wheel.

Base body:aluminum or steel,the role of supporting the working layer.

Transition layer:consisting of a binding agent, metal powder and fller, the connection of the working layer and the base body.

Advantages:

1)electroplated process is simple, less investment, convenient manufacture;

2)No need to trim, easy to use;

3)monolayer structure determines the it can achieve very high working speed, currently , has been as high as 250 ~ 300m / S;

4)although only a monolayer diamond, but there is still enough life time;

5)for the high precision request rolling wheel, electroplated is the only manufacture method.

Comparison of CBN and Diamond Use:

Due to the different physical and chemical properties of diamond and cubic boron nitride, it is necessary to make appropriate choices based on the workpiece material processed.

| Comparison of CBN and Diamond Uses | |||

| Diamond | application | ||

| Cemented carbide, Diamonds,quartz,Concrete,asphalt | tungsten cast iron aluminium alloy magnetic material | |

| CBN |  | carbon steel, high speed steel,chisel tool steel,chilled steel,Die steel,Bearing steel,stainless steel,copper alloy,heat-resisting alloy,Superalloy | |

| Body Type and introduction of diamond & CBN grinding wheel | |||

| Body Type | Introduction | ||

| Steel |  | 1. Steel body has the best rigidity. 2. Steel has a higher melting point than aluminum and is used for dry grinding. 3. The weight is the heaviest of the three. | |

| Aluminum |  | 1. The weigh lighter than steel body. 2. Aluminum has a low melting point, so need to be grinding with water 3. Aluminum suitable for polishing. | |

| Plastic |  | 1. The weight is the lightest of the three. And the freight is relatively low. 2.The rotational speed should be faster than the steel body when use. 3. Plastic body has the advantages of light weight and low price. | |

Application:

Electropalted Diamond Wheels can be used in many industries, stone polishing, glass polishing polishing. Electroplated CBN wheels can be used in woodworking tool sharpening, HSS Tool sharpening, Carbide Tool Sharpening.