Basic Info.

Packaging & Delivery

Product Description

Introduction:

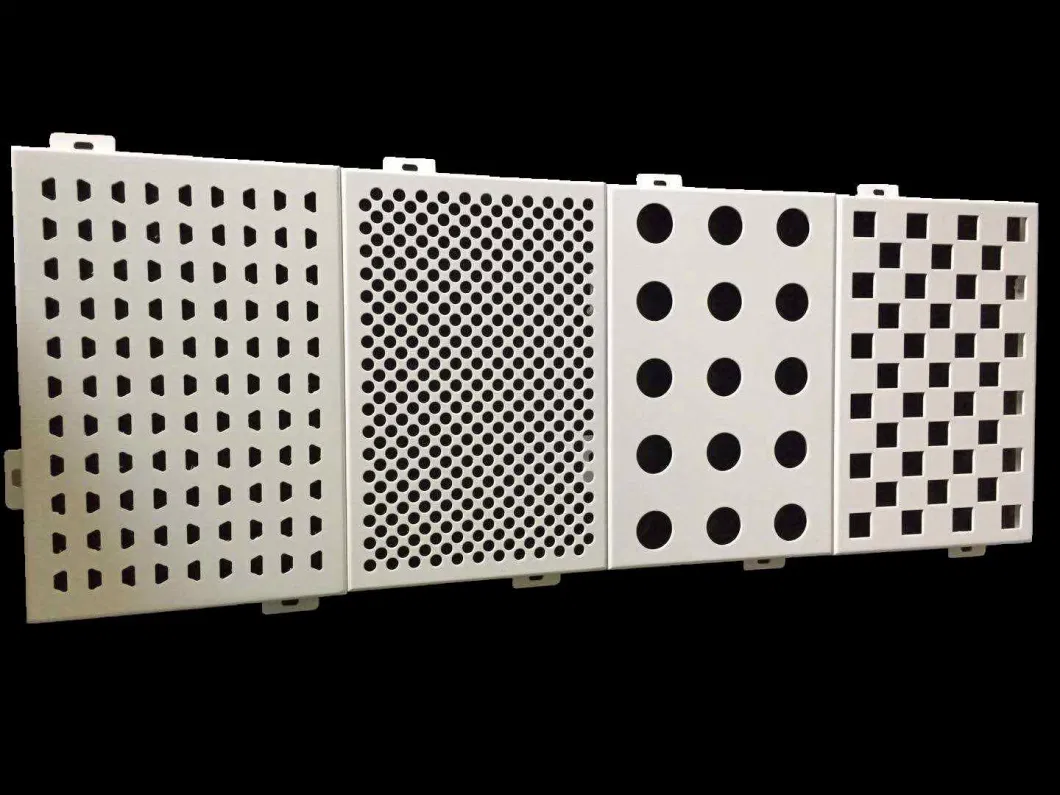

The thickness of carved aluminum panel is decided by panel size and the height of the building. The thickness we used mostly is from 1.5mm~4mm, it is easy to be processed into various kinds of sizes and patterns. The carved panel mainly use CNC or Lasser cut engraving equipment, it is can be made into different ceilings , curtain wall, the hollow pattern pattern of column cover, according to different requirements.

Features:

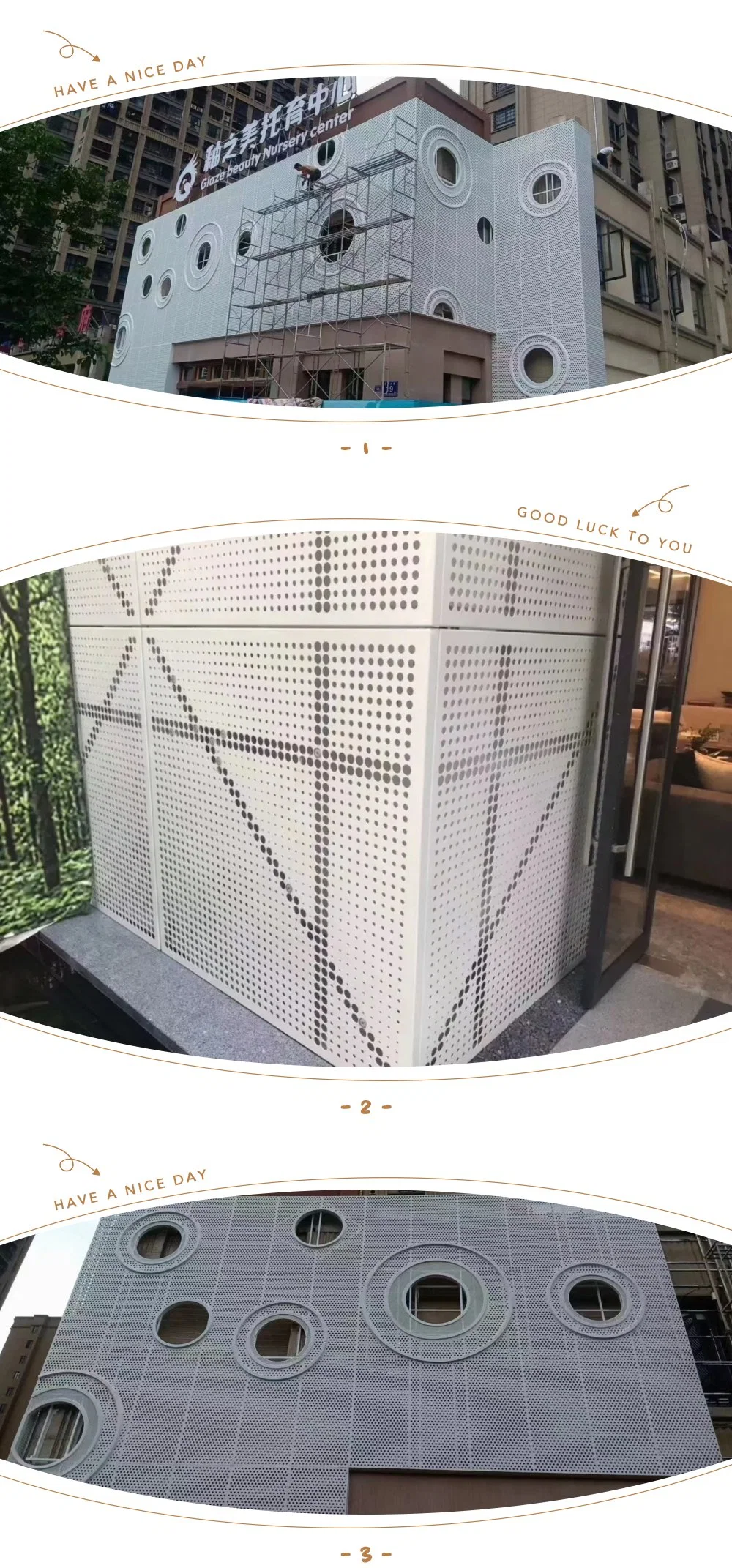

Difference design of carving panels provide the flat panel with sense of space which will be more lighting and ventilate. Difference designgives a innervation , It is more suitable for moderen high-class clubs, home decoration, office and so

on. It is bring unlimit image for fashion people. This New decortaion format is utility and beautiful.

Specification:

| Product Name: | Decorative Aluminum Panels |

| Materials: | Aluminum Alloy AA1100 and AA3003 series |

| Thickness: | 1.5mm~10mm |

| Surface Treatment: | Powder Spray Coating; PE(Polyester) Spray Coating; PVDF( Fluorocarbon Coating) |

| Painting: | KCC, PPG, Akzo Nobel, Becker , ect. |

| Color: | Solid color, Metallic Color, Wooden/stone color, ect. |

| Size: | Stand size:1000mm X 2000mm; Or base on your drawing size. |

Certificates: | ISO 9001:2000; ISO 4001 |

Application: | Cladding , facade, fence, wall canopy, ceiling, screen. window, balcony, privacy panel, ect. |

| Patterns: | Any pattern can be made, just supply us your design drawing. |

Hotsell Design:

For more designs please feel free contact me, or we can prduce base on your design drawing.

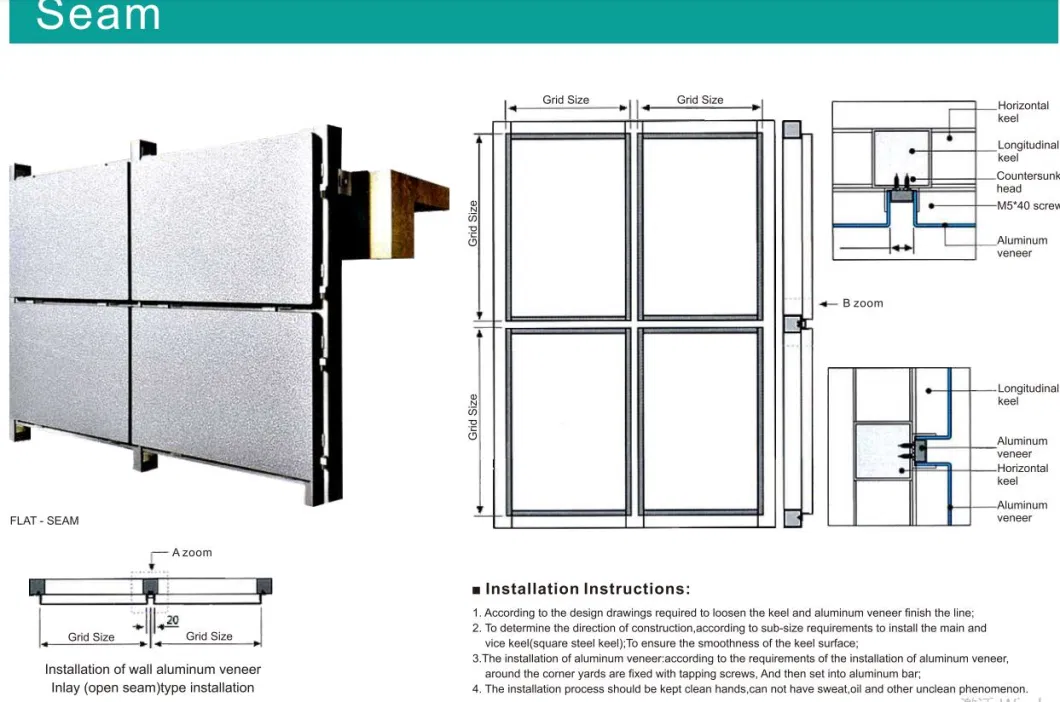

Install way:

Project Show:

Color Choose: (Color also can customized)

Advantages of Aluminum Wall Panel:

2.Good weather ability and good corrosion resistance.

3.Can be curved with customized patterns.

4.Three-dimensional view to match the building structure.

5.Strong Anti-seismic and fireproof performance.

6.High resistance to moisture and corrosion.

7.Coating uniform, varied color choices.

8.Not easy to stain, convenient to clean and maintain.

9.Easy for installation and cost-effective.

10.Recyclable, friendly to the environment.

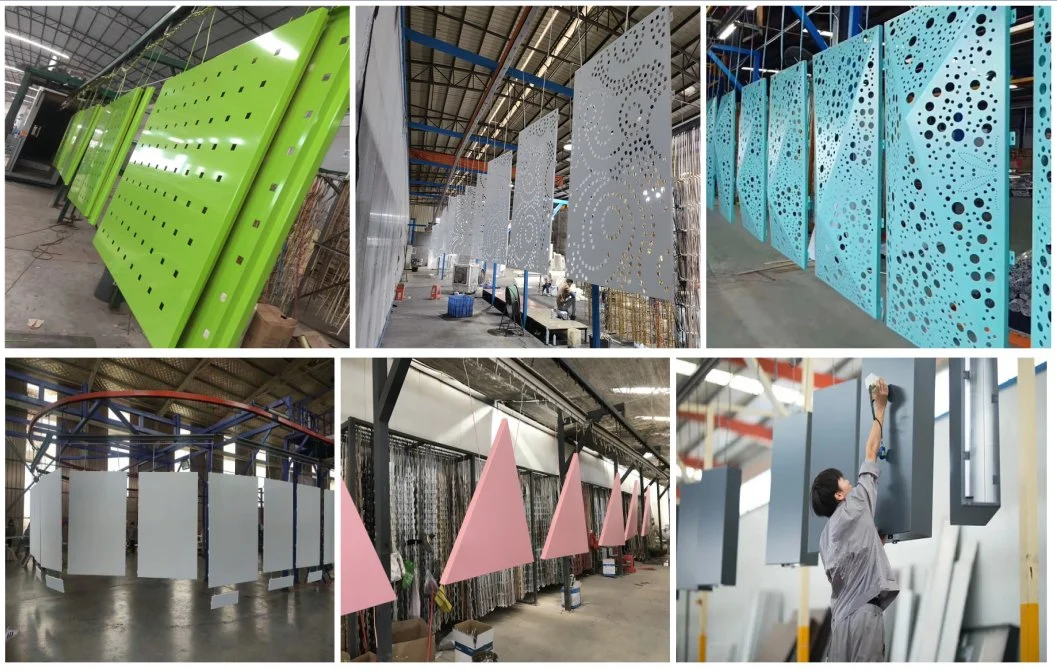

Production Procedure:

Sheet metal procedure

Cutting/Blanking - Score - Incidence Angle(Punch hole, NOtch) - Bending - Welding - Burnishing - Rib Assembling - Rivet Assembling -

Polishing - Checking-Spray Coating.

Spray coating procedure

Skim - - Alkali - Corrosion-Blare-Elimination (by acid) - Chromizing - Drying - Spraying - Solidifying-Baking - Inspection.

Workshop:

Packing & Shipping:

Welcome to our factory

FAQ